-

简体中文

简体中文

-

English

English

PART 1. INTRODUCTION OF AT9S Pro

1.1 SAFETY PRECAUTIONS

- Do not use the remote controller in the rain! Avoid moisture entering the transmitter. If it is unavoidable to use this product in humid weather (such as competitions), please cover your remote controller and receiver with a waterproof cloth, and do not fly if there is lightning.

- Don’t use it in rainy and snowy weather. This weather environment will interfere with the remote controller equipment, resulting in loss of control and accidents!

- Don’t use this equipment in crowded areas and places prohibited by national laws and regulations!

- Do not allow children (Less than 14 years old) to touch this product. This product is not a toy. Please be careful when operating in scenes where children are present.

- Please strictly abide by local laws and regulations when flying to ensure safe flight!

- Make sure the throttle stick and trim button are set at the lowest end before turning on, then turn on the power button and check whether the power supply is sufficient, then turn on the receiver!

- Check whether the various actions of servo are consistent with the direction of the corresponding joystick before operating the model. If they are inconsistent, please adjust before using!

- Please turn off the receiver and controlled equipment before stopping use, and then turn off the power supply of the transmitter. If the operation is reversed, it may cause loss of control and cause an accident!

- The operating voltage of transmitter is 7.4V~18V. Please do not use battery outside this voltage range when replacing the battery by yourself.

- You can choose 8 dry battery or 2S~4S lithiumbattery to power the transmitter. Please learn about the characteristics of lithium battery and use the professional lithium battery charger. Improper operation may cause permanent damage and risk of fire.

- There is a Micro USB port at the bottom of AT9S Pro. Please note the port is for upgrading firmware, not for charging.

1.2 Basic introduction of AT9S Pro

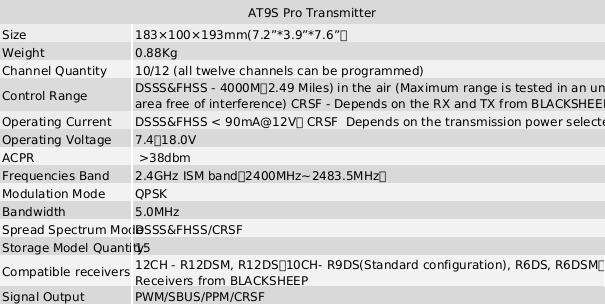

1.2.1 Technical Parameters

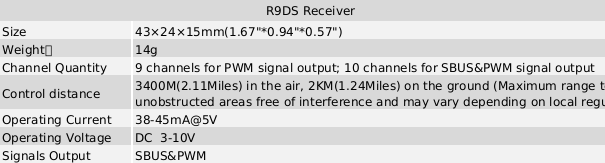

1.2.2 Configuration List

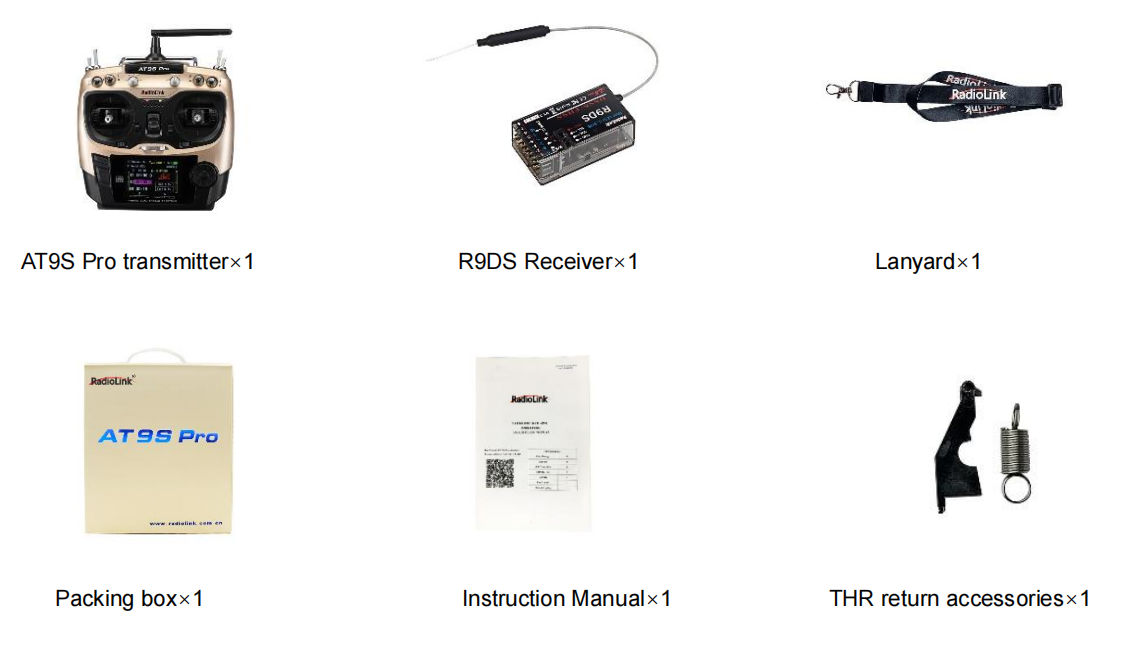

1.2.3 Recommended Configuration

The below accessories sold separately. You can enter the Aliexpress Official Store to purchase. Or login to the Radiolink official website for product details.

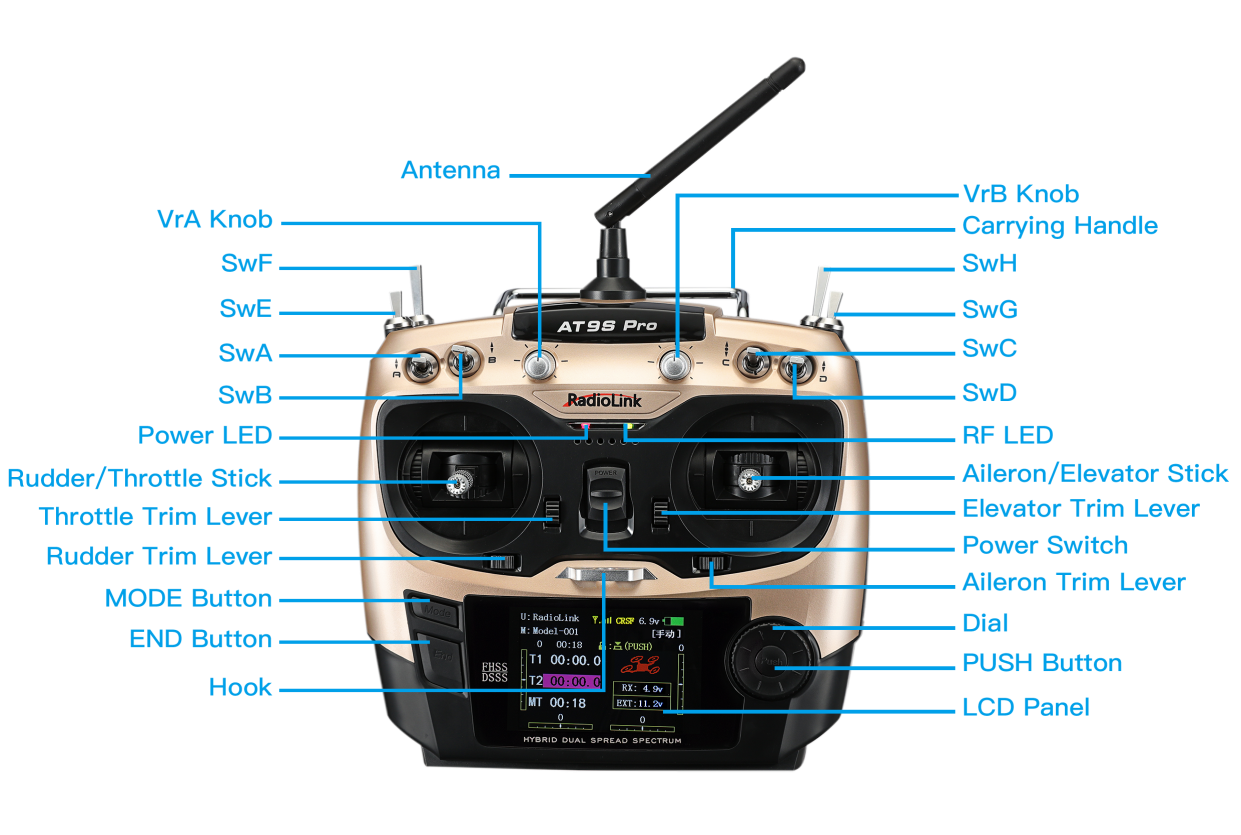

1.2.4 Transmitter

1.2.5 Basic Usage and Settings

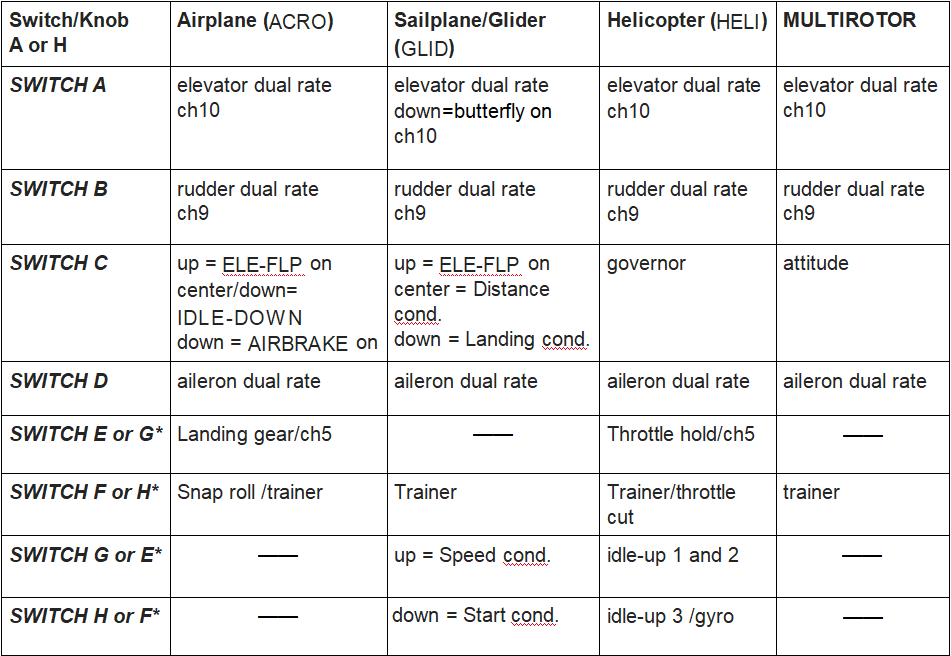

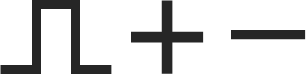

SWITCH ASSIGNMENT TABLE

• The factory default functions activated by the switches and knobs for a AT9S Pro transmitter are shown below.

• Most AT9S Pro functions may be reassigned to non-default positions quickly and easily. Always check that you have the desired switch assignment for each function during set up.

1.2.6 Transmitter Displays

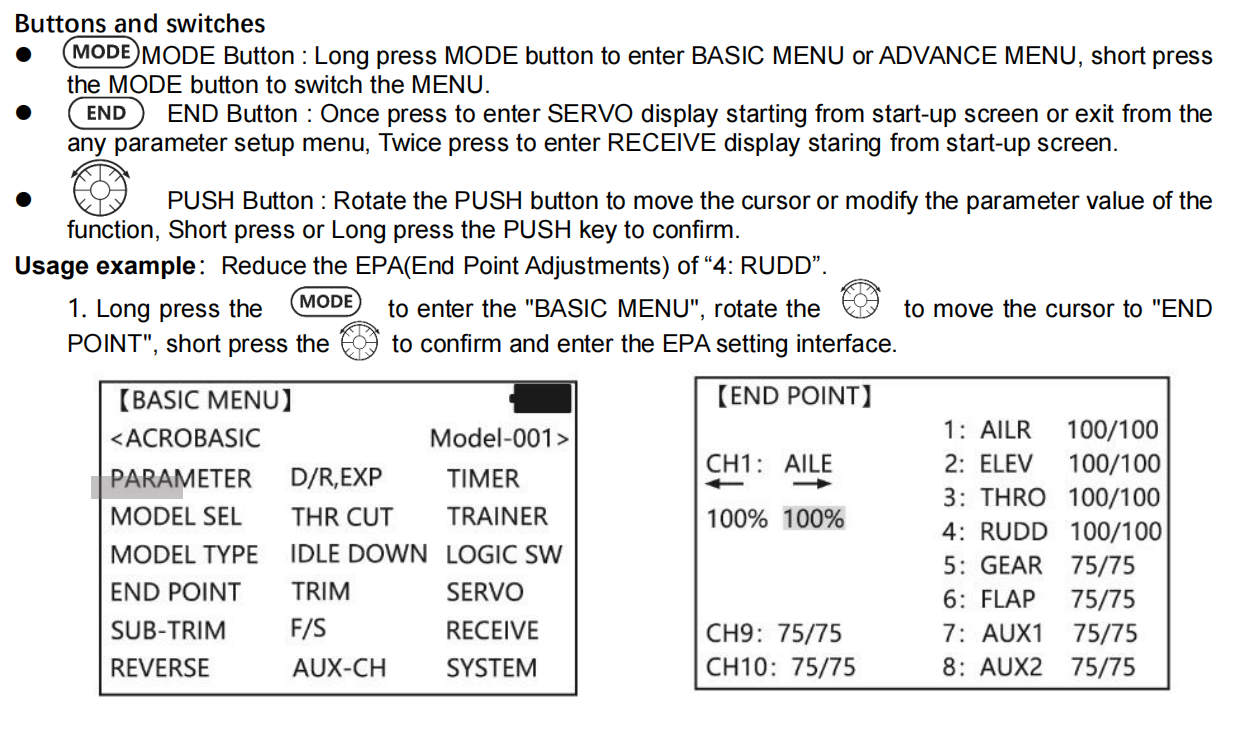

Transmitter Displays & Buttons

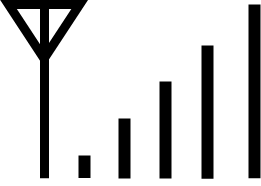

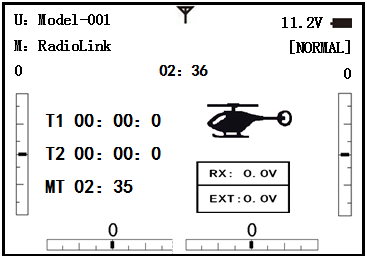

When you first turn on your transmitter, a confirmation double beep sounds, and the screen shown below

The model name and the user name. Before flying, or even starting the engine, be sure that the model type and name appearing on the display matches the model that you are about to fly! If you are in the wrong model memory, servos may be reversed, and travels and trims will be wrong, leading to an immediate crash.

The signal tower. When it is connected to the receiver successfully, there will be a signal It shows the signal strength between the transmitter and the receiver. After connection with TBS crossfire transmitter, there will be a signal of CRSF.

The signal tower. When it is connected to the receiver successfully, there will be a signal It shows the signal strength between the transmitter and the receiver. After connection with TBS crossfire transmitter, there will be a signal of CRSF.

The voltage of the transmitter and the flight attitude.

The boot time of the transmitter.

T1/2 for Timer 1/2. You can set a timer for flight time to avoid crash caused by over discharging and low voltage of the battery. You can also set it to control limited time function for Flight fixed maneuvers.

The boot time of the model. You can also set other timer function in the menu.

After successful connection between the transmitter and the receiver, RX will shows the voltage of the receiver.(When using receiver R6DS, R6DSM and R12DSM, RX will not be displayed )

After connecting with telemetry module such as PRM-01 or PRM-01, EXT will shows the model voltage. You can buy it on RadioLink official website.

Take model 2 left hand as an example. There are 4 calibrated scale on the screen edges, which represents the trimming of aileron, elevator, throttle and rudder, corresponding to four trimmer button on the transmitter. Do not use trimmer button before first flight. It is suitable to trim flight attitude during first horizon flight.

ALARMING

When the transmitter is powered on, warning or error may happen by the following probability

Battery low voltage alarming

Lithium battery 2S-4S can fit for the transmitter, warning voltage can be self-set according to different battery.

Setting step: power on the transmitter, press and hold MODE one second to enter basic menu, and press PUSH to enter PARAMETER. Choose TX ALARM by DIAL and PUSH to change relative data. Suggested min voltage is not less than 7.4V.

When the transmitter voltage is less than the setting voltage, it will beep till the transmitter is powered off. Most important thing is to land your model plane when the transmitter alarms.

2. Mixing alarm

When the transmitter alarms mixing, it means at least one mixed switch is active. And when it is inactive, warning will stop then. When the transmitter is powered on, in different model type, mixing switch is shown as below:

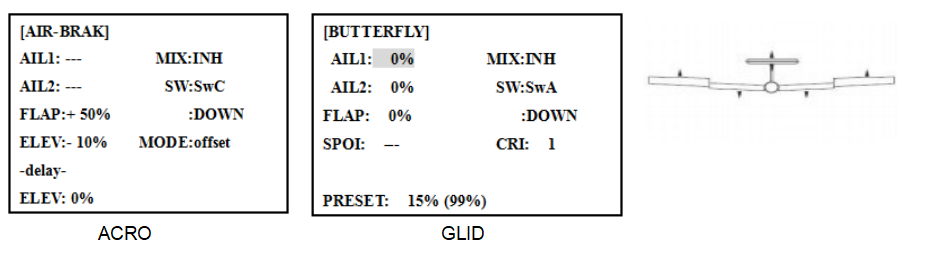

ACRO: throttle cut, idle down, snap roll, air brake

GLID: butterfly, condition

HELI: throttle cut, throttle lock, speed up

If the warning continues even the related switch is set OFF, probably it is because some programs mixed by one switch and status OFF reversed. Now you need to set mixing alarm again by DIAL.

3. Throttle down alarm

When the transmitter alarms THR POSITION, rotate PUSH to stop the alarm. It is mainly for reminding the user to keep the throttle at the lowest position to operate safely. If the user want to turn off the alarm, go to basic menu- SYSTEM. Set TH-DOWN to OFF.

1.3 Receiver

1.3.1 Compatible Receivers

AT9S Pro is a 10 channels transmitter, support 2.4G DSSS and FHSS dual hybrid spread spectrum, 16 channels pseudo random frequency hopping.

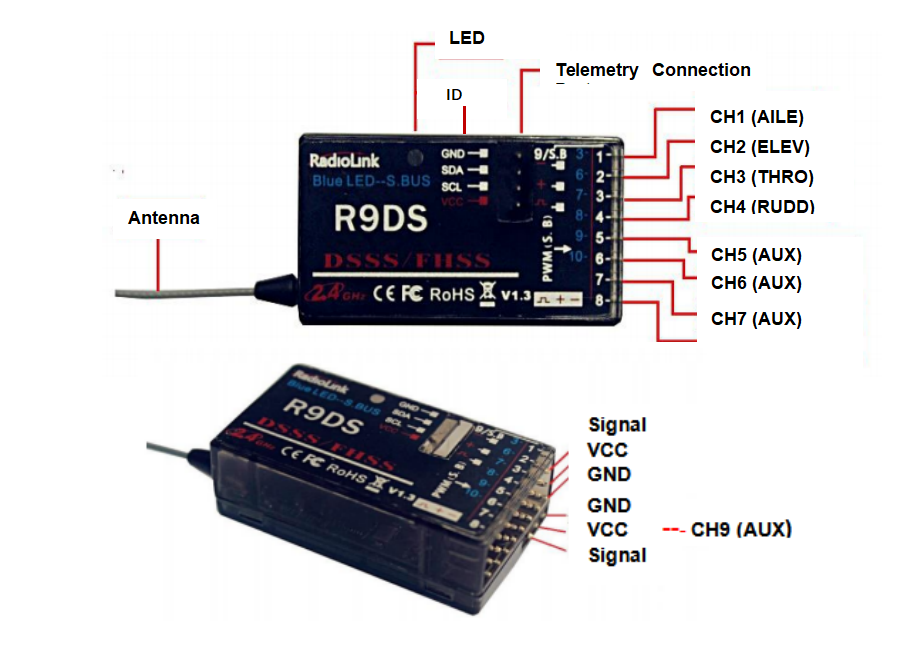

AT9S Pro sells with receiver R9DS.

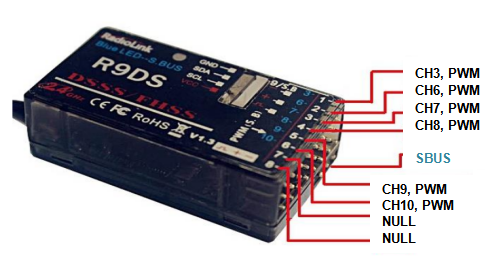

R9DS is a 9 channels receiver when working with PWM signal(red LED), it will a 10 channels receiver when working with S-BUS signal(purple/blue LED).

Besides R9DS, AT9S Pro is also compatible with Radiolink R6DS, R10DS, R12DS and super mini 10 channels receiver R6DSM and 12 channels mini dual antenna receiver R12DSM.

R6DS, is a 6 channels receiver when working with PWM signal while it is a 10 channels receiver when working with SBUS or PPM signal.

R12DS, is a 11 channels receiver when working with PWM signal while it is a 12 channels receiver when working with SBUS signal.

Note AT9S Pro is default 10 channels, you can upgrade it to 12 channels with USB cable. You have to setup AT9S Pro to 12 channels first if you use 12 channels receivers R12DS or R12DSM while you have to setup AT9S Pro back to 10 channels when you use 10 channels receiver R6DS, R6DSM and R10DS.

To setup to 12 channels: power on your AT9S Pro--Press Mode button one second into BASIC MENU--into SYSTEM menu--change CH-SELECT from 10CH to 12CH.

Since RadioLink radio control systems are not open source, RadioLink transmitters are just compatible with RadioLink receivers and vice versa.

When AT9S Pro is connected with TBS Crossfire TX, it only supports crossfire receiver.

1.3.2 Two signal working modes of R9DS

There are two signal working modes, PWM and SBUS&PWM signal output. Short press ID SET twice within 1s, the working mode will change.The RED led indicates the PWM output and BLUE/PURPLE led indicates SBUS signal.

(1) PWM signal output working mode:RED led indicates PWM signal output, 9 channels totally

(2) SBUS&PWM dual signal output working mode: blue/purple LED indicates SBUS&PWM signal output at the same time with 10 channels totally. CH9 outputs SBUS signal while the original CH1 outputs CH3 PWM signal and original CH2 to CH6 output CH6 to CH10 PWM signal at the same time.

1.3.3 The connection of the receiver

Dupontthread is used to connect the receiver. The common color is white/red/black or yellow/red/brown. The signal wire is light color, while the ground wire is dark color. The three wires are corresponding to . When connecting with the servo wires, the signal wire is upward and the ground wire is downward.

. When connecting with the servo wires, the signal wire is upward and the ground wire is downward.

Note: All RadioLink receivers are designed with Anti-polarity connect protection. When the connection of the servo wires are reversed, the receiver will stop working and it won’t be damaged. But when connecting the servo at this time, the servo may be damaged.

The below chart is to introduce the default output channel of the receiver when setting different models. Take acrobatic as an example.

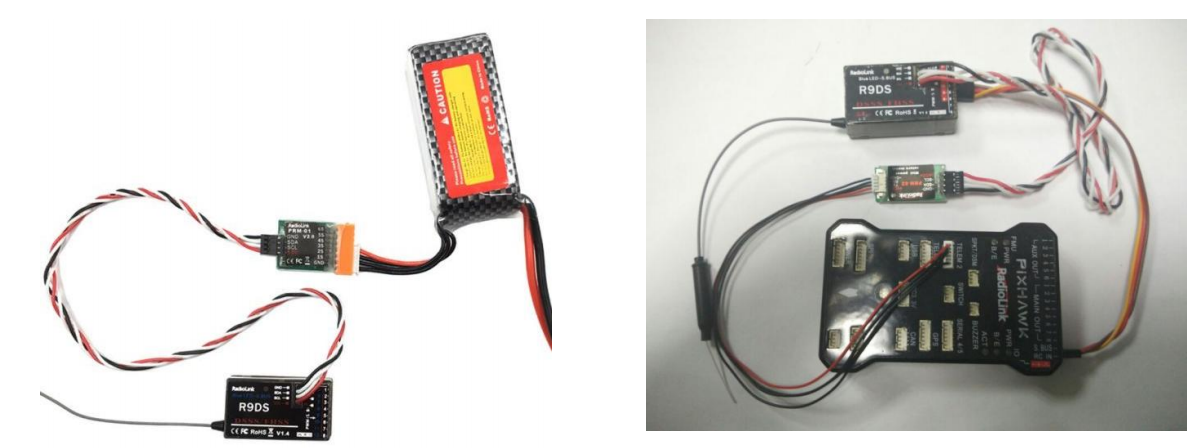

The connection between the receiver and the model voltage telemetry module

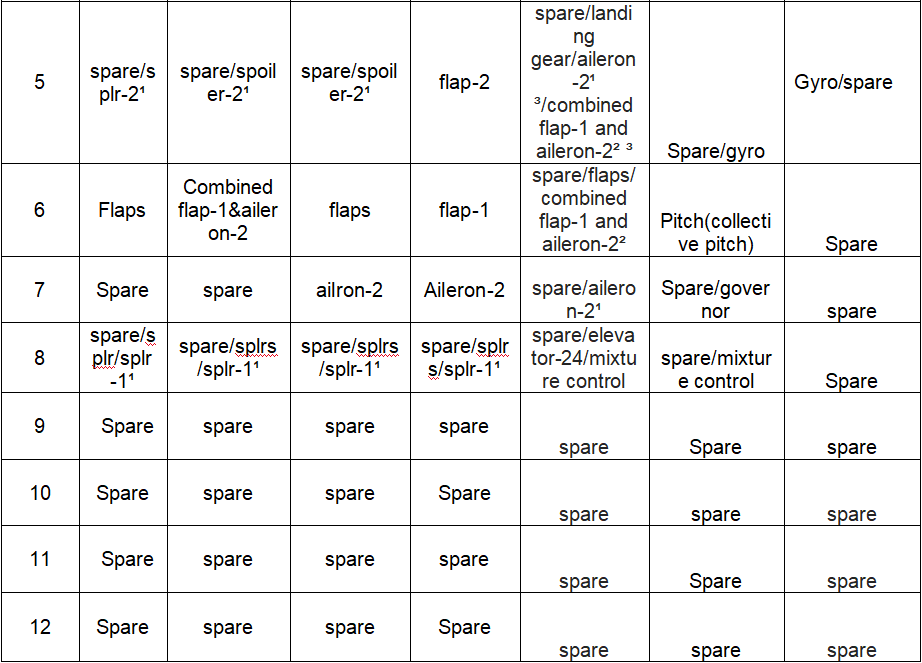

How to connect PRM-01with the receiver

PRM-01 shows real-time model Voltage. When the voltage is low, the transmitter will vibrate with beep sound. And there is text prompt on the screen. The flight will be safer.

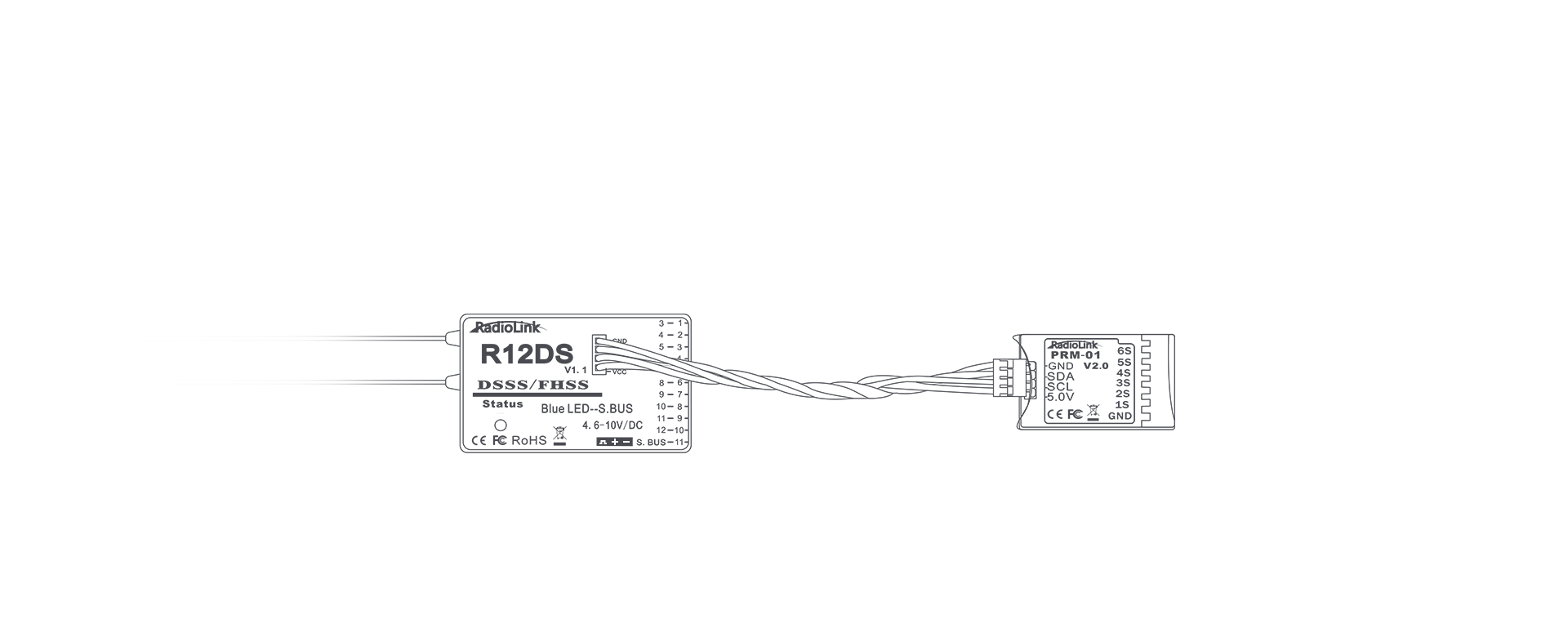

PRM-03 Real-time OSD information telemetry module

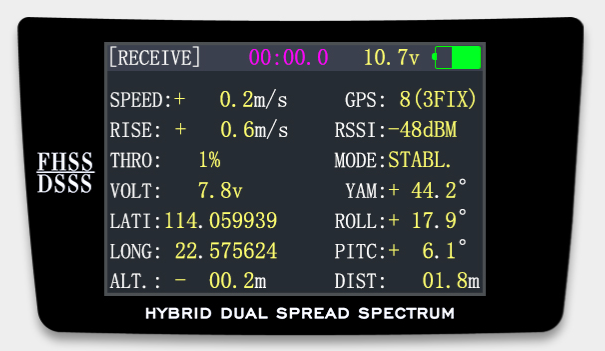

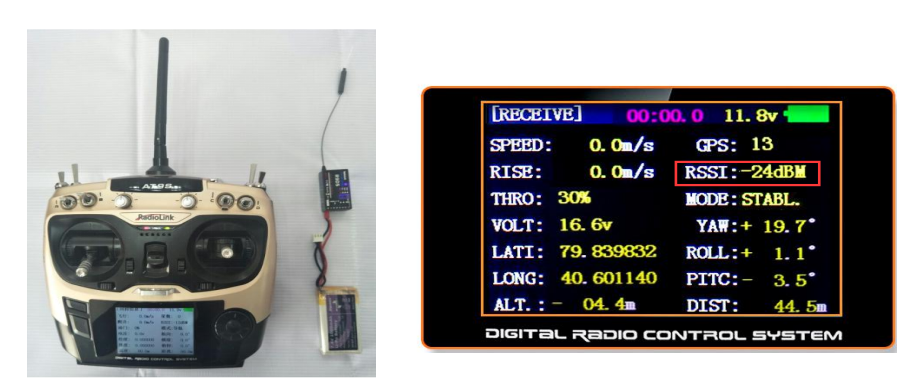

Real-time model data allows users to receive crucial information on the model's systems. With flight module PRM-03 and flight controller PIXHAWK/Mini Pix/TURBO PiX, model voltage, speed, climb, throttle, longitude, latitude, altitude, GPS, RSSI, flight mode, yaw, roll, pitch, and distance are display on the transmitter screen.

Telemetry modules are sold separately. You can enter the Aliexpress Official Store to purchase. Or login to the RadioLink official website for product details.

1.3.4 Binding

Each transmitter has an individually assigned, unique ID code. Receiver should bind to transmitter before starting operation. Once binding is complete, the ID code will be stored in the receiver and no further binding is necessary unless the receiver is used with another transmitter. When you purchase a new R9DS, this procedure is necessary; otherwise the receiver will not work.

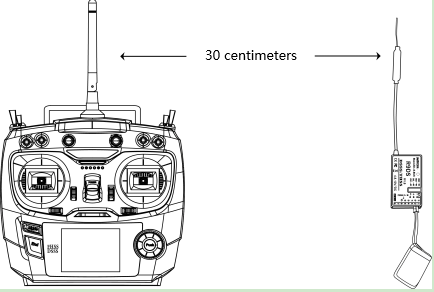

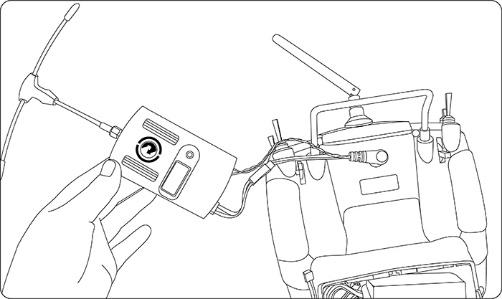

1. Put the transmitter and the receiver close to each other about 50 centimeters.(much too close distance may cause signal jamming)

2. Power on AT9S Pro and receiver R9DS.

3. Turn on AT9S Pro and it will automatically bind with the closest receiver. Turn on AT9S Pro. Long press ID SET,which is on the side of receiver for more than 1 second and release until the RED/PURPLE LED flashes. When the LED stops flashing and is always on , binding is complete.

4.  at the top of the screen means it hasn’t finished binding or the failure of binding. Bind again until you see

at the top of the screen means it hasn’t finished binding or the failure of binding. Bind again until you see . at the top of the screen.

. at the top of the screen.

Please note: Since RadioLink radio control systems are not open source, RadioLink transmitters are ONLY compatible with RadioLink receivers. When the transmitter connect with TBS Crossfire TX, it supports crossfire receiver.

1.3.5 Installment of antenna

Installment of antenna

Receiver Antenna Installment

- Keep antennas as straight as possible, or the effective control range will reduce.

- Big models may contain metal parts that influence signal emission. In this case, antennas should be positioned at both sides of the model to ensure the best signal status in all circumstances.

- Antennas should be kept away from metal conductor and carbon fiber at least half inch away and no over bending.

- Keep antennas away from motor, ESC or other possible interference sources.

- Press and hold the ID SET for more than one second and receivers will start to work with the RED LED on.

Note Receiver contains some electronic components of high-precision. Be careful to avoid strong vibration and high temperature.

When all the above steps are complete, please turn off the transmitter and repower on to test if the receiver is correctly connected with it.

Transmitter Antenna Installment

1、The transmitter antenna is adjustable so please make sure that the antenna never points directly at the model when flying as this may possibly decrease the receiver signal.

2、Keep the antenna perpendicular to the transmitter to optimize the receiver performance. It also depends on how you hold the transmitter. But in most cases, adjusting the antenna with perpendicular position to the transmitter surface will achieve the best result. Please adjust the transmitter antenna according to the way you hold the transmitter.

3、Never grip the antenna when flying as this degrades= effective control range.

1.3.6 RSSI testing

Before flight, always remember to do the RSSI testing to avoid the possible unexpected signal loss. Power on transmitter and receiver, keep them with the distance of about 30 centimeters and both antennas straight.

Enter the parameter setup menu by press MODE one second, you can check the RSSI in RECEIVE.

The RSSI is 0 to 30dBm is normal when the transmitter is apart about 30 centimeters from the receiver, the signal is more better the RSSI data is more close to 0.

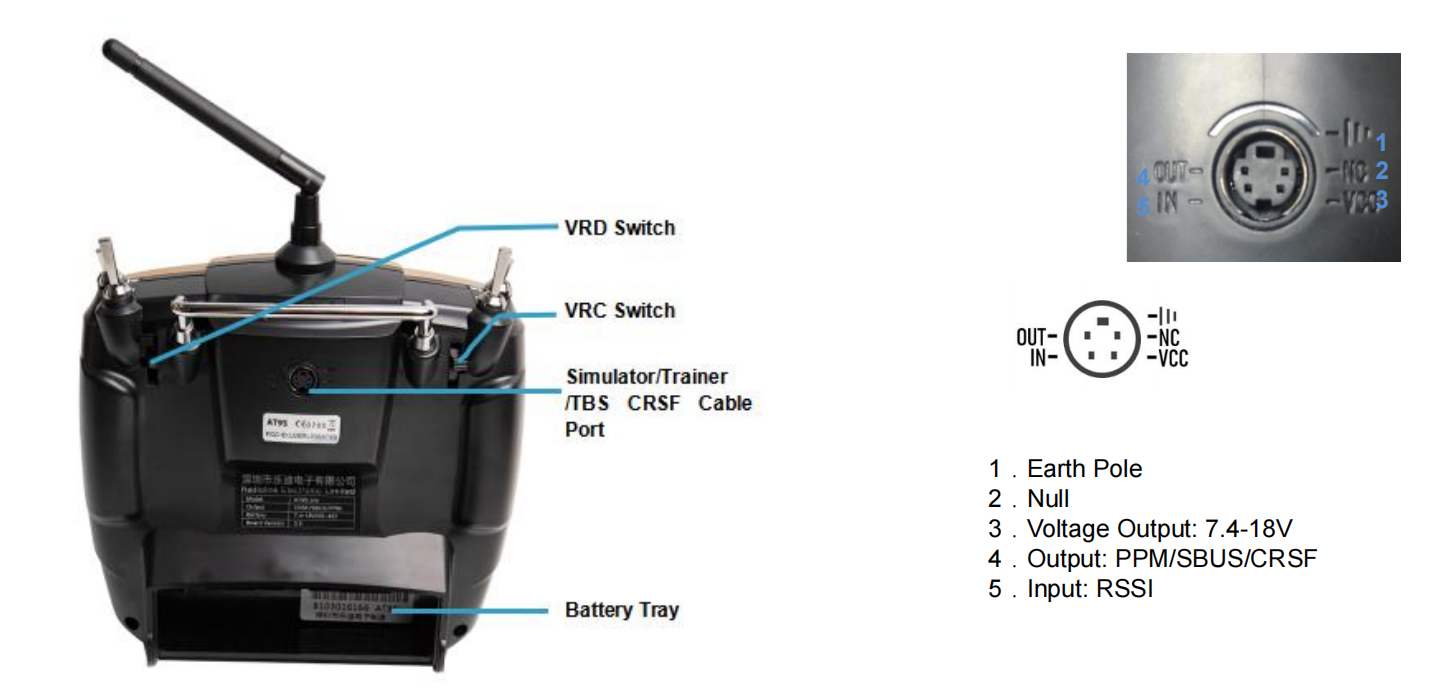

1.4 Connection with TBS Crossfire TX

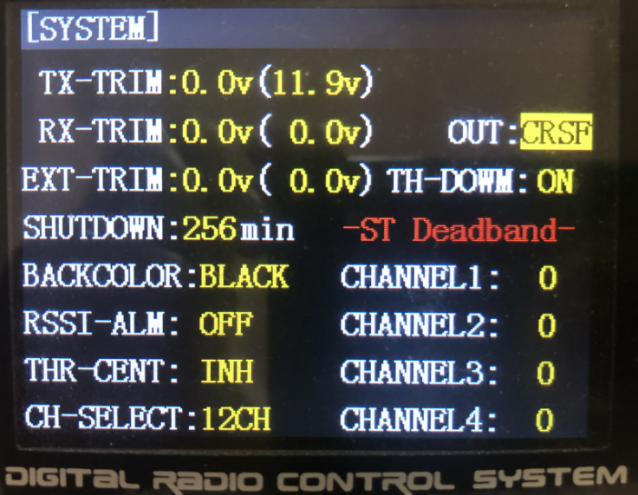

1、Power on the transmitter- Long press the Mode key to enter the BASIC MENU->Rotate the Scroll Dial to highlight the SYSTEM option and depress the Enter key->Select the OUT and change the output as CRSF

Note:The setting is to define the signal output of the simulator port at the back of AT9S Pro. If the simulator or trainer cord to connect, there are other output options as SBUS and PPM.

2、Connect TBS crossfire transmitter with the CRSF cable to the simulator port at the back of AT9S Pro.

3、After the binding of TBS Crossfire TX and receiver, check if there is“CRSF”next to the signal tower at the screen, which means TBS Crossfire TX can work properly.

The detailed steps please refer to the video tutorial https://youtu.be/g_mfHdeEQCo

Note: The compatibility function with TBS Crossfire TX is only available in AT9S Pro, which CANNOT be upgraded from AT9S directly.

PART 2. BASIC FUNCTION OF AT9S Pro

The BASIC menu is suitable for all type models, including airplane, helicopter, glider, MULTIROTOR, cars and boats. Please go to PART 3 for advance menu.

2.1 PARAMETER

In PARAMETER, you can set LANGUAGE, STK-MODE, RF-MODE, BACKLIGHT, USER NAME, TX-ALARM, RX-ALARM, EXT-ALARM, LockScreen and sound. You can also check the firmware version. If you need to download the latest firmware, please click the link here: www.radiolink.com/at9spro_firmwares

Display language: can be selected the display language of the function name, etc. in each function menu. The screen reads "LANGUAGE". Change this to the desired language. Go to BASIC MENU- PARAMETER- LANGUAGE to select.

RF Mode: includes on and off. The LED indicator will become solid green when RF Mode is active. Set RF mode to OFF to save energy when using the simulator. Set RF mode to on when operating the model.

BLACKLIGHT: change number to adjust the intensity of the backlight. 20 indicates the brightest scrren. 0 indicates the darkest screen.

USER NAME: user name can be set by DIAL and PUSH with letters and numbers.

Alarming voltage

TX-ALARM: The minimum voltage alarm of transmitter. It can be self-set. When it is below the minimum voltage, the transmitter will vibrate and sound the alarm. The recommended voltage is 7.4V for 2S lithiumbattery, 11.1V for 3S lithiumbattery, 14.8V for 4S lithiumbattery.preset 8.6V.

RX-ALARM: The minimum voltage alarm of receiver. It can be self-set. When it is below the minimum voltage, the transmitter will vibrate and sound the alarm.

EXT-ALARM: The minimum voltage alarm of Telemetry module. It can be self-set. When it is below the minimum voltage, the transmitter will vibrate and sound the alarm.

Note: the RX-ALARM is only available when the transmitter connects to PRM-01 or PRM-03 Telemetry module. Telemetry module sold separately. You can enter the Aliexpress Official Store to purchase. Or login to the Radiolink official website for product details.

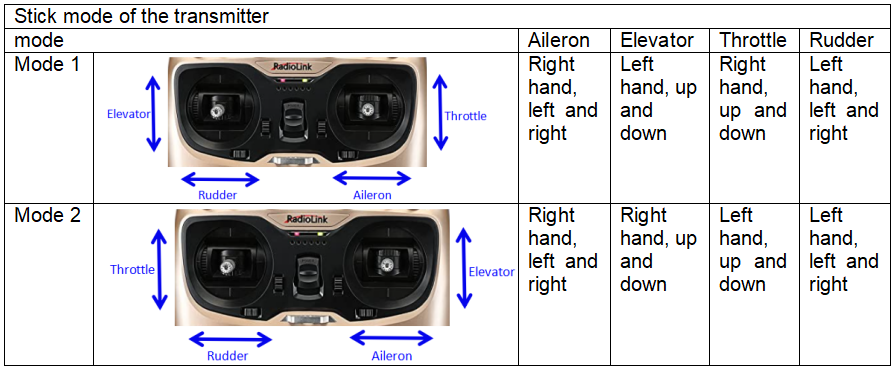

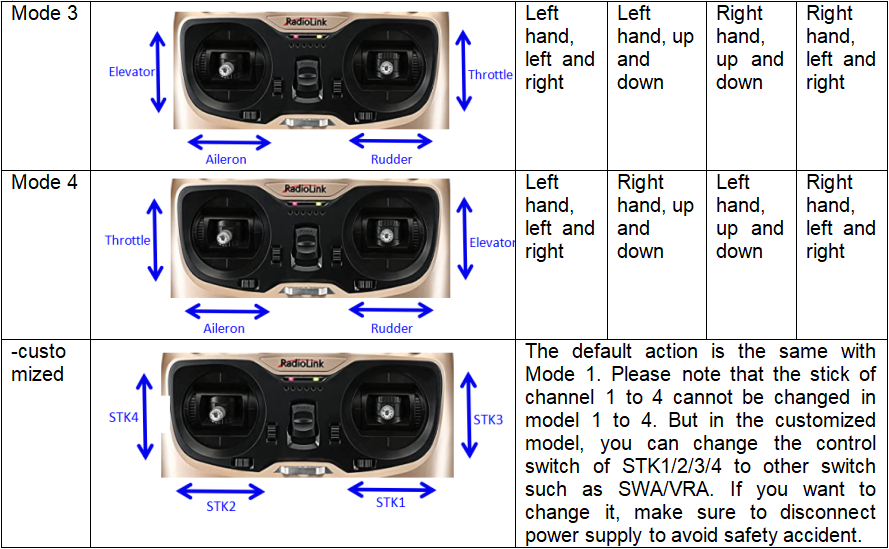

Stick Mode: The screen reads "STK-MODE". Change this to the correct mode. Note that this will NOT change the throttle and elevator ratchets, etc. Those are mechanical changes that must be done by a service center.

There are 5 stick models.

LockScreen: It can be set to OFF or “1s-254s”, When it is set to “1s-254s”, the screen will be locked if there is no operation in this time period. The setting is to avoid wrong operation during flight. Long press push button for 1 second to unlock the screen.

Sound: When it is on, there is sound when setting the function or alarming. When it is off, there is no sound.

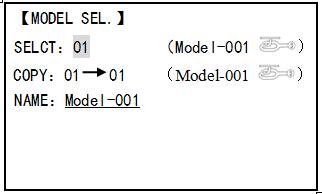

2.2 Model Select

Model submenu: includes three function that manage model memory: MODEL SELECT,MODELCOPY and MODEL NAME. Since these functions are related, and all basic features are used with most models, they are together in the Model submenu.

Totally there are 15 models stored in the system, followed by model name and plane type to use on tap, thus you don’t need to set every time for different plane. MODEL NAME, MODEL TYPE and transmitter voltage. Make sure that MODEL TYPE is accomplished with your plane type before flight. Or it will cause error in servo and rudder.

Select

Press Push button to choose the model you want. Long press push button to confirm and press End button to come back to the menu.

Caution: Do not switch the model when the model is powered on. Disconnect power supply of the model when switching model. After selecting model, enter the basic menu-Reverse. Set the throttle to reverse.

COPY

Save the present data as another model type, it will be displayed by shadow area to differ from. When this copy start, the object data will be fully covered including name, type and module type, and cannot recover.

Caution: when you save the present model type as another, all related data will be copied including the original model name. Accordingly, if you want to change the model type, the whole data need to reset, also for model name. The first thing to copy is to change the model type or delete the original name and rename a new model to avoid confusion.

Caution: when you save the present model type as another, all related data will be copied including the original model name. Accordingly, if you want to change the model type, the whole data need to reset, also for model name. The first thing to copy is to change the model type or delete the original name and rename a new model to avoid confusion.

Model Name

This is used to set the present model name. Name all model to identify each other, and fast select the model type and reduce possible crash by wrong model type using.

Format to name a model:

•the name can be more than 9 characters

•every character can be letter, number, blank or special characters

•factory setting name MODEL-XXXX will be shown as (example model 1 display MODEL-0001)

COPY→PC

Turn on the function when you need to copy the data of the model to computer to avoid data reset. Connect the transmitter with computer and use the RadioLink official app to copy the data.

Example | Select Model 5, copy the data of Model 5 to Model 3, and change the name of Model 5 to A-560 |

Steps | Go to NAME. Press Push and turn Push to choose character to name the model. |

2.3 Model Type

Model Type is to select models, reset and some other functions.

Data reset

All set data can be reset to factory setting. This function will not delete all model type set in the radio.

Setup step:

Enter the basic menu for MODEL TYPE, use dial to choose a proper type and press PUSH for one second, when the screen displays “are you sure”, press PUSH and the radio will beep, and it is set to factory data.

Caution: don’t power the radio off before setting is finished, or the setting is invalid. The reset is only for this type. If you want to reset all settings, you need to reset every type.

Type

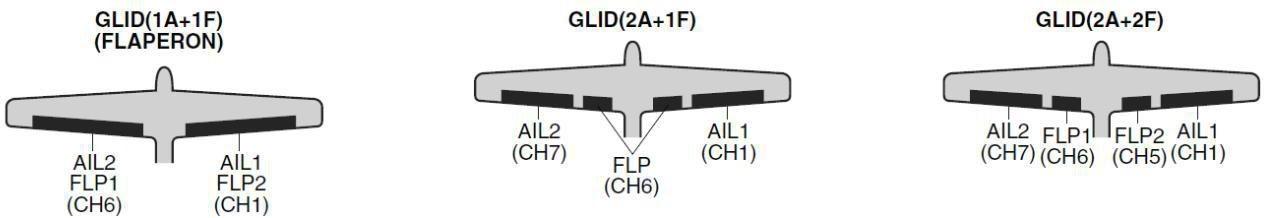

You can choose the suitable type according to your model, including helicopter, acrobasic, glid(2A+1F), glid(2A+2F), multirotor, car and boat.

Setup step:

Enter the basic menu for TYPE, use dial to choose a proper type and press PUSH for one second, when the screen displays “are you sure”, press PUSH.

Different models have different advantages. For example:

Fixed wing models: idle down、throttle shut、throttle needle mix,snap roll etc.

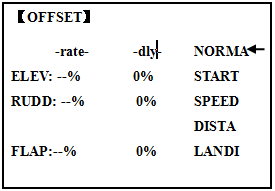

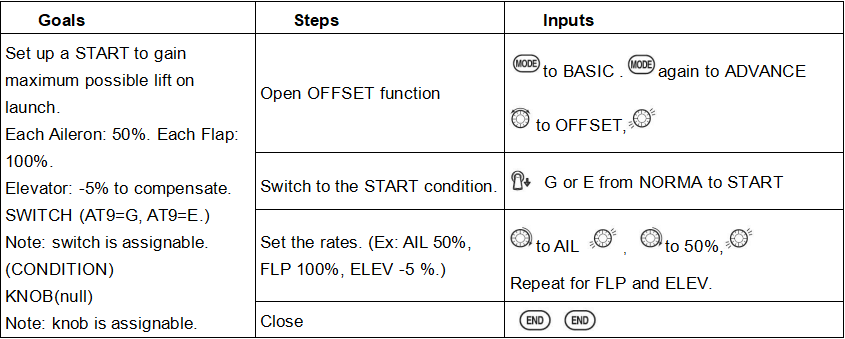

Glider: different tail type, 5 individual flight conditions etc.

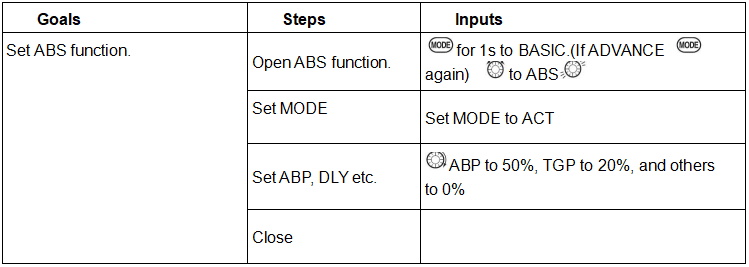

Car: A.B.S. etc.

You can choose the suitable models to get different functions.

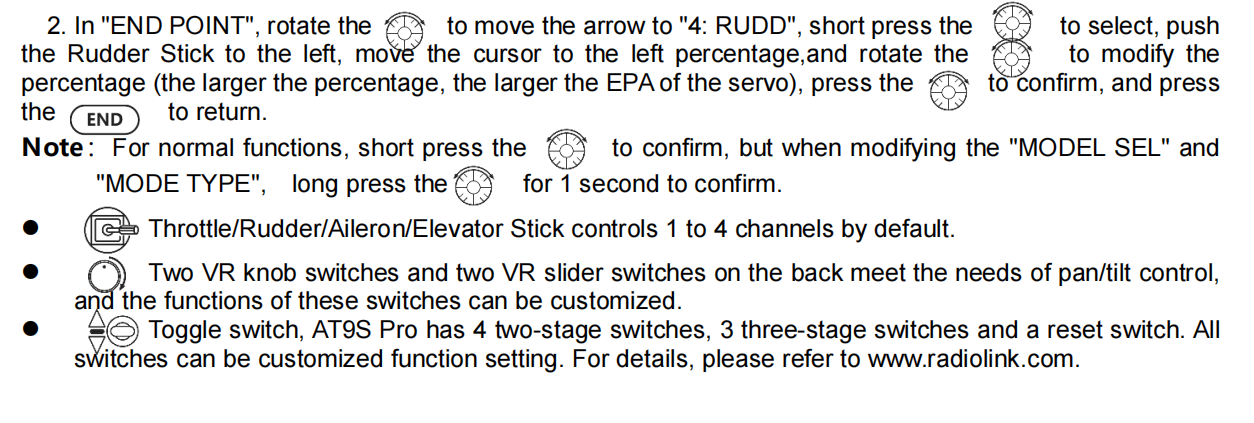

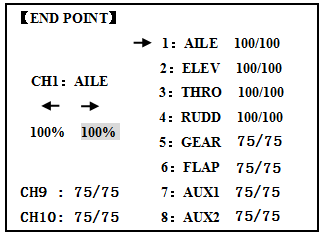

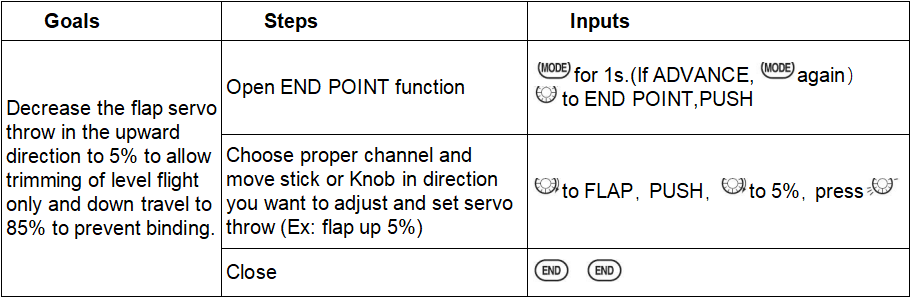

2.4 End Point (also called EPA)

EPA is set to to end points of each servo. Users can adjust it from 0% (no servo movement at all) to 140%. Reducing the percentage settings reduces the total servo throw in that direction. Increasing the percentage settings increases the total servo throw in that direction.

The most flexible version of travel adjustment is available. It independently adjusts each end of each individual servo’s travel, rather than one setting for the servo affecting both directions. Again, for CCPM helicopters, be sure to see SWASH AFR prior to adjusting end points.

Adjustability:

• Can set each direction independently.

• Ranges from 0% (no servo movement at all) to 140%. At a 100% setting, the

Throw of the servo is approximately 40°for channels 1-4 and approximately 55°for channels 5-8.

• Reducing the percentage settings reduces the total servo throw in that direction.

Examples:

• Adjust the throttle high end to avoid binding at the carburetor, and low end to allow for proper carburetor closure.

• END POINT may be adjusted to 0 to keep a servo from moving one direction, such as flaps not intended to also operate as spoilers.

• Retract servos are not proportional. Changing END POINT will not adjust the servo.

END POINT adjusts only the individual servo. It will have no effect on any other servo that is operated in conjunction with this servo via mix or preset programming such as FLAPERON, AILEVATOR, etc. This is so that each individual servo can be carefully fine-turn to avoid binding and other conflicts. To adjust the total travel of a function such as FLAPERON, make the adjustments in that function's controls. For CCPM helicopters, adjust the total travel of the function, such as collective pitch, in SWASH AFR. Adjust the linkage or the END POINT? It is nearly always best to adjust your linkages to get as close as possible prior to utilizing END POINT. The higher the END POINT setting, the better position accuracy and the more servo power available at nearly any position (except if using digital servos). Higher END POINT values also mean longer travel time to reach the desired position, as you are utilizing more of the servo's total travel. (For example, using 50% END POINT would give you only half the steps of servo travel, meaning every click of trim has twice the effect and the servo gets there in half the time). End point (and moving the linkage) = torque, accuracy, but transit time to get there.

• END POINT (instead of adjusting linkages) = travel time, but torque, accuracy.

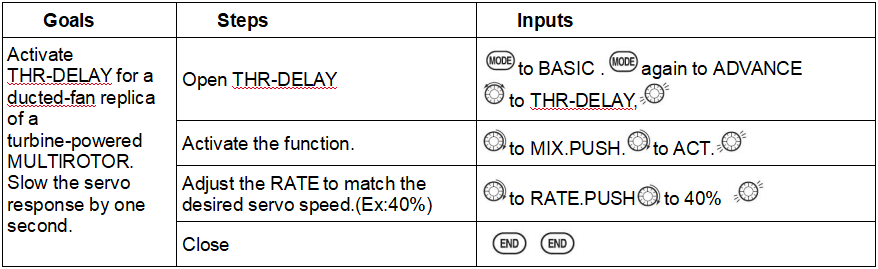

Engine idle management: IDLE-DOWN and THR-CUT: functions which work with the digital THROTTLE TRIM to provide a simple, consistent means of engine operation. No more fussing with getting trim in just the right spot for landings or take offs! For additional engine adjustments, see THROTTLE-NEEDLE and THROTTLE DELAY.

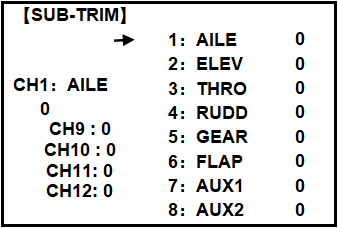

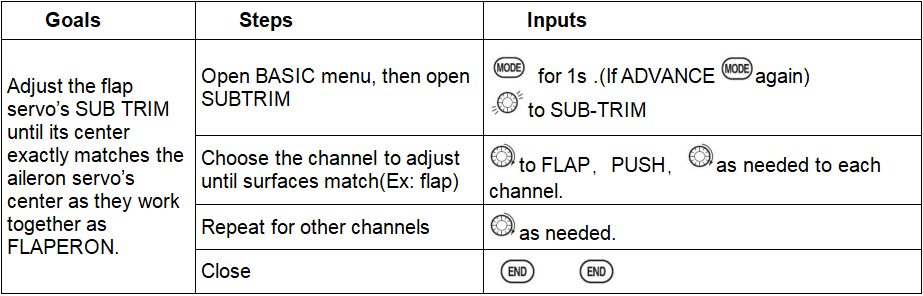

2.5 SUB TRIM

SUB-TRIM: makes small changes or corrections to the neutral position of each servo. Range is -120 to +120, with 0 setting, the default, being no SUB-TRIM.

We recommend that you center the digital trims before making SUB-TRIM changes, and that you try to keep all of the SUB-TRIM values as small as possible. Otherwise, when the SUB-TRIM is of large values, the servo's range of travel is restricted on one side.

The recommended procedure is as follows:

• Measure and record the desired surface position;

• Zero out both the trims (TRIM RESET menu) and the SUB-TRIM (this menu);

• Mount servo arms and linkages so that the control surface’s neutral is as correct as possible; and

• use a small amount of SUB-TRIM to make fine corrections.

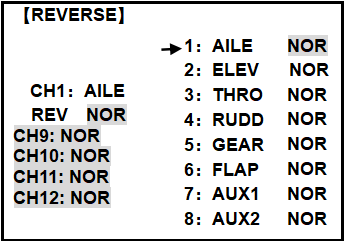

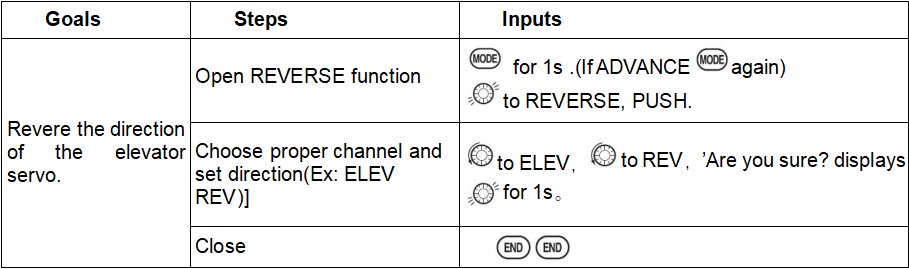

2.6 Servo Reversing (REVERSE)

Changes the direction an individual servo responds to a CONTROL STICK motion.

Except with CCPM helicopters, always complete your servo reversing prior to any other programming. If you use pre-built ACRO/ GLID functions that control multiple servos, such as FLAPERON or V-TAIL, it may be confusing to tell whether the servo needs to be reversed or a setting in the function needs to be reversed. See the instructions for each specialized function for further details.

Always check servo direction prior to every flight as an additional precaution to confirm proper model memory, hook ups, and radio functions.

Caution: Always make sure servo of throttle in channel 3 is reverse and then charge the model. Do not change the model type when it is charging. It may cause serious consequences if the throttle is not reverse.

Servo reversing

2.7 Dual rates and exponential (D/R,EXP)

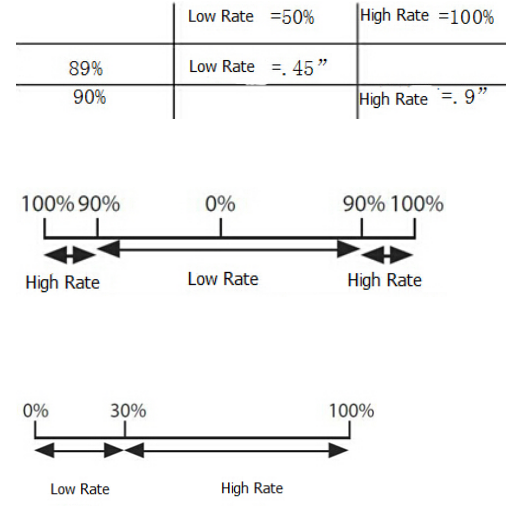

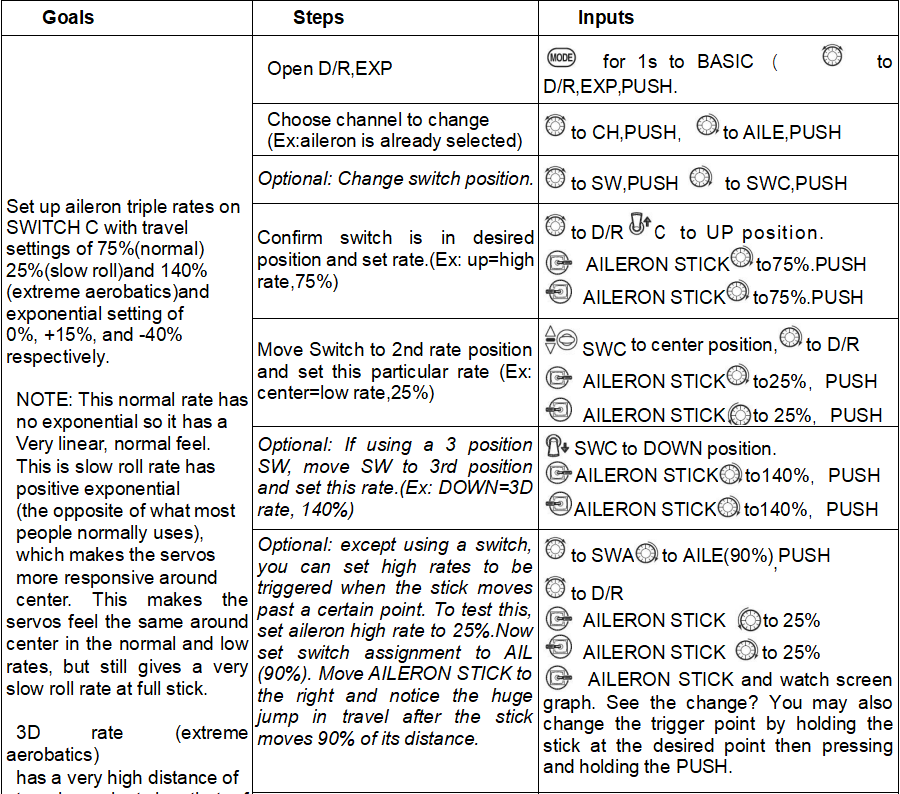

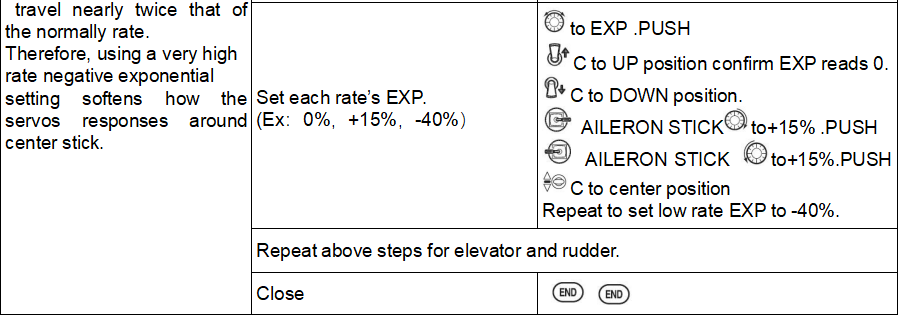

Dual/Triple Rates: reduce/increase the servo travel by flipping a switch, or (ACROGLID) they can be engaged by any stick position. Dual rates affect the control listed, such as aileron, not just a single (ex: channel 1) servo. For example, adjusting aileron dual rate will affect both aileron servos when using FLAPERON or AIL-DIF, and both aileron and elevator servos’ travel when using AILEVATOR or ELEVON or a CCPM helicopter.

Activation:

• Any SWITCH, A-H. If you choose a 3-position switch, then that dual rate instantly becomes a triple rate.

• The glider programming offers you the choice of Condition. This option allows you to have a separate rate for each of condition. (GLID)

• Stick position (ACROGLID). (Ex: On rudder you normally use only the center 3/4 of the stick movement except for extreme maneuvers such as snaps/spins/stalls. As long as your RUDDER STICK does not exceed 90% (ie. stall turn), the rudder goes to high rate's 90%, which is a MUCH higher amount of travel than your low rate at 89%)

Adjustability:

• Range: 0 - 140% (0 setting would deactivate the control completely.) Initial value=100%

• Adjustable for each direction (ACRO/ GLID)

(i.e. Up/down, left/right) (Ex: Most models fly upright without any elevator trim, but require some down elevator when inverted just to maintain level flight. By increasing the down travel by the amount required to hold the model inverted, the model now has equal travel available from level upright or level inverted.

Only if any stick is chosen by the item of "SW1", a switch can also be chosen by the item of "SW2." When operated simultaneously, the switch operation has priority over the stick operation. (ACRO)

Only if any stick is chosen by the item of "SW1", a switch can also be chosen by the item of "SW2." When operated simultaneously, the switch operation has priority over the stick operation. (ACRO)

Exponential:

Change the response curve of the servos relative to the stick position to make fly more pleasant. You can make the servo movement less or more sensitive around neutral for rudder, aileron, elevator, and throttle (except HELI type use THROTTLE CURVE instead). (ACRO type throttle EXP and THROTTLE CURVE can not be activated simultaneously). Many models require a large amount of travel to perform their best tricks.

However, without exponential, they are touchy around neutral, making them unpleasant to fly and making small corrections very difficult. Additionally, by setting different exponentials for each rate, you can make the effectiveness of small corrections similar in each rate, as in our example below:

The best way to understand exponential is to try it:

• Having made no changes yet in the D/R, EXP screen, move SWITCH D to DOWN (toward the AILERON STICK).

• Move SWITCH D up. Hold the AILERON STICK at 1/4 sticks and moves SWITCH D down.

• Notice how much less travel there is.

• Go to 3/4 stick and repeat. Notice how the travel is much closer, if not identical.

Adjustability:

• More sensitive around neutral. (Positive exponential)

• Less sensitive around neutral. (Negative exponential)

• Adjustable for each direction. (ACRO/GLID)

For throttle, exponential is applied at the low end to help nitro and gasoline engines have a linear throttle response, so that each 1/4 stick increases engine RPM 25% of the available range. (In most engines this ranges from 5-60%)

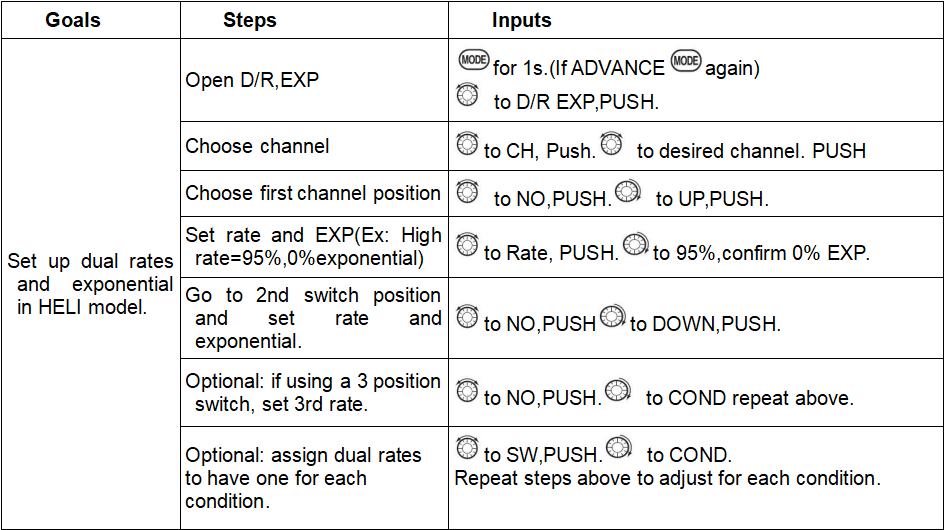

Special note for helicopters: Helicopter model types have just a single rate for each switch position rather than a rate for each side of the servo's travel per switch position. Additionally, setting the D/R, EXP for each switch position requires cursor back to the No. setting and changing the switch position here. Just flipping the switch does not affect the screen setting, allowing dual rates to be assigned with idle-up and other features on certain switches, and does not require putting the model in that condition to make modifications.

Special note for helicopters: Helicopter model types have just a single rate for each switch position rather than a rate for each side of the servo's travel per switch position. Additionally, setting the D/R, EXP for each switch position requires cursor back to the No. setting and changing the switch position here. Just flipping the switch does not affect the screen setting, allowing dual rates to be assigned with idle-up and other features on certain switches, and does not require putting the model in that condition to make modifications.

Special note for conditions: The helicopter and glider programming offers you the choice of COND. This option allows you to have a separate rate for each of the 3 controls automatically selected when changing conditions, for a total of FIVE rates available. Simply change the switch choice to COND. and then:

(HELI) press the CURSOR LEVER to toggle through the 5 conditions while setting the rates.

(GLID) activate the corresponding condition to edit the rates.

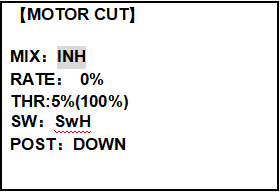

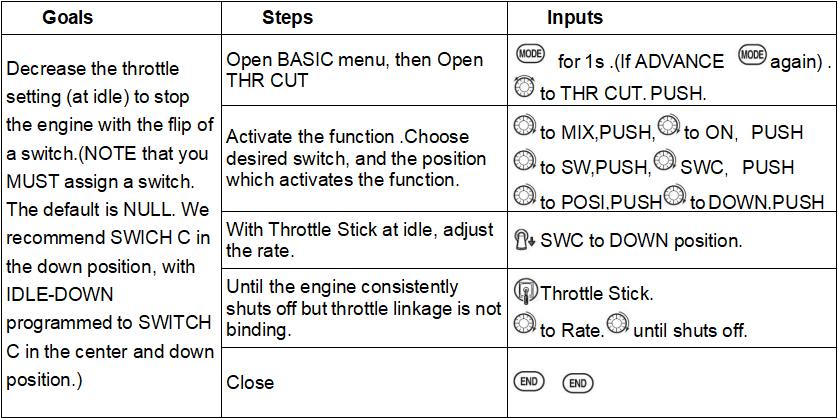

2.8 MOTOR CUT (Throttle Cut)

ACROBASIC

MOTOR CUT/Throttle cut (THR-CUT) (ACRO/HELI): provides an easy way to stop the engine by flipping a switch (with THROTTLE STICK at idle). The movement is largest at idle and disappears at high throttle to avoid accidental dead sticks. In HELI, there is an additional setting.

The switch's location and direction must be chosen. It defaults to NULL to avoid accidentally assigning it to a switch, which might result in an unintentional dead stick in flight.

* Also LOGIC SW(Lsw1 to 3) may be assigned.

** Normally, a setting of 10-20% is sufficient. Viewing the carburetor barrel until it fully closes is adequate to get an approximate setting; then test with engine running to confirm.

GLIDER

Provides an easy way to stop the engine by flipping a switch no matter where the air brake stick is. The movement of servo will be -30%. Now you must select switch position and direction. Factory setting the position is NULL to avoid an accident setting on a switch to cause glitches during flight.

Adjustability:

• Range: -30% to +30%. Movement of servo is 0%, air brake stick is on its min and -30% on the max.

• SWA-H and logic switch Ls1-3 is selectable

• All position is available for logic switch including NULL (usually MIX OFF), you can set MIX by different position of a switch (UP & CEN, CEN & DN) and also NORM, REV.

HELICOPTER

This function is used to stop engine after flight is finished. You can set engine powered on/ off, without shifting trim stick to power off and set again every time before flight. Throttle shut for helicopter includes THR ON/ OFF (position above idle down). Before resetting throttle cut, throttle stick must keep below setting point to avoid a sudden speeding up.

Notification: trigger point setting step: under the menu THR CUT, choose THRO by DIAL, and press PUSH and move the throttle stick to trigger point, then press and hold PUSH one second to save. This function only when the throttle stick moves below trigger point.

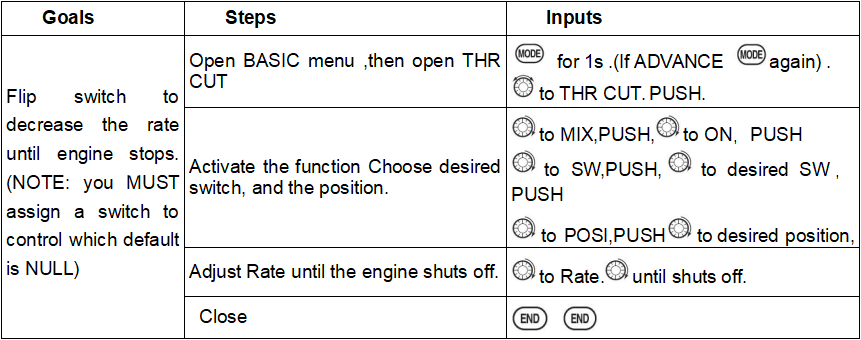

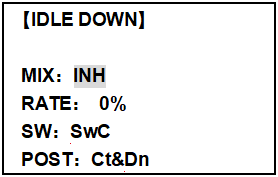

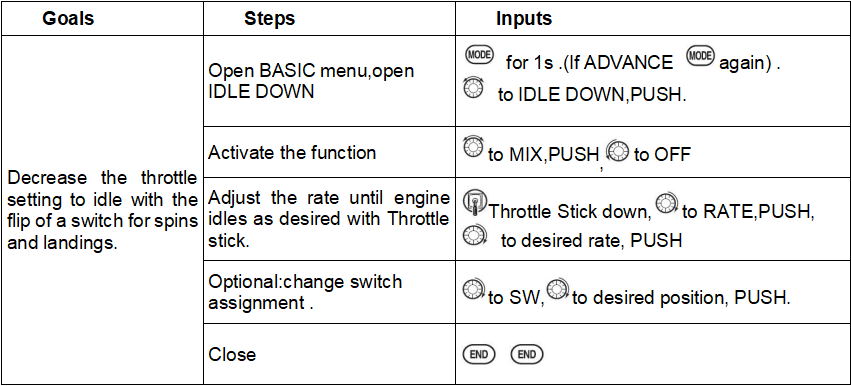

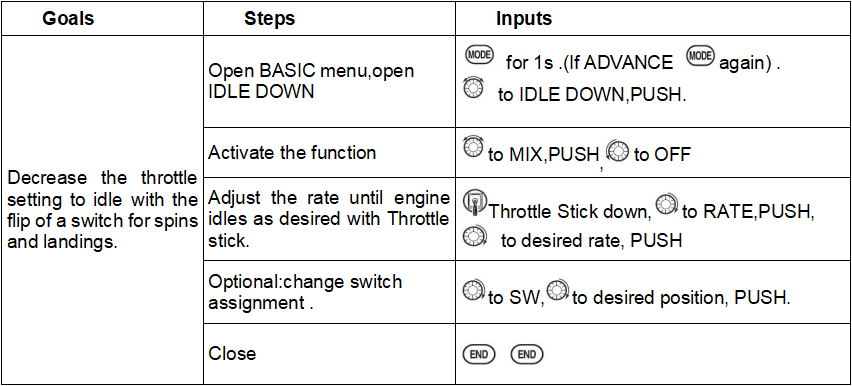

2.9 IDLE DOWN (ACRO only)

Lowers the engine idle for: set for sitting on the runway prior to take off, stalls and spins, and landings. The normal idle setting is a little higher for easier starts and safe flights with less risk of dead sticks.

Important note: The IDLE-DOWN function is not normally used when starting the engine, and its accidental operation may keep your engine from starting. The AT9 warns that IDLE-DOWN is on when the transmitter is turned on. Be sure to turn off the function, or override the warning by pressing CURSOR lever if you intended the function to be on.

This may be assigned to any switch/position. Some modelers accidentally assign IDLE-DOWN to one side of a switch and THR-CUT to the other. There is no "normal" setting to start the engine. By default IDLE-DOWN is get to SWITCH C center and down. This works well with THR-CUT also on SWITCH C down. The SWITCH C up is normal flight/starting, center for slower maneuvers/landing, and down to cut the engine. If you assign IDLE-DOWN or THR-CUT to the spring-loaded TRAINER SWITCH H or F, then use the trainer function, you

may risk loss of throttle control or dead stick for your student.

*Normally a value of 10- 20%. Secure the fuselage, engine running. Set the THROTTLE STICK to idle. Adjust the IDLE-DOWN switch ON and OFF until the desired idle is achieved. Be sure to throttle up periodically to allow the engine to “clean out” and idle reliably.

*Also LOGIC SW (Lsw1 to 3) may be assigned.

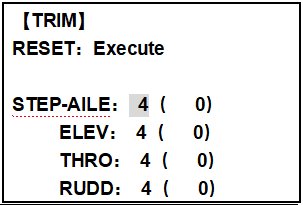

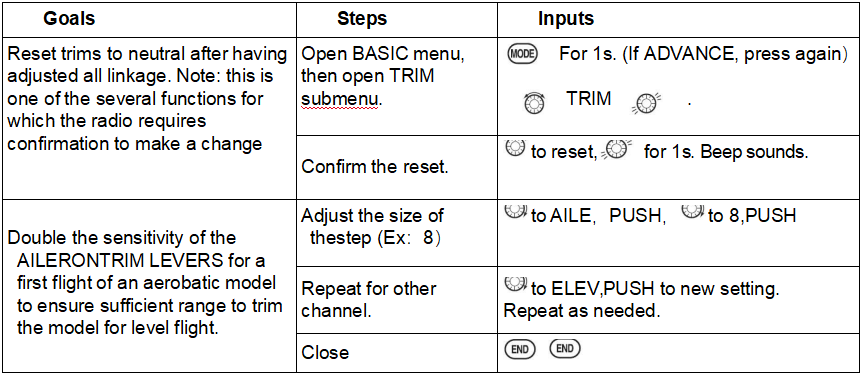

2.10 TRIM

TRIM submenu: resets and adjust effectiveness of digital trims.

The AT9 has digital trims which are different from conventional mechanical trim sliders. Each TRIM LEVER is actually a two-direction switch. Each time the TRIM LEVER is pressed, the trim is changed a selected amount. The amount defaults to 4. When you hold the TRIM LEVER, the trim speed will increase. The current trim position is graphically displayed on the start up screen. The TRIM submenu includes two functions that are used to manage the trim options.

Trim reset (RESET): Electronically centers the trims to their default values. Note that the SUB-TRIM settings and the trim STEP rate are not reset by this command.

Trim step (STEP): changes the rate at which the trim moves when the TRIM LEVER is activated. It may be set from 1 to 40 units, depending on the characteristics of the MULTIROTOR. Most ordinary MULTIROTOR do well at about 2 to 10 units. Generally larger trim steps are for models with large control throws or for first flights to ensure sufficient trim to properly correct the model. Smaller trim steps are later used to allow very fine adjustments in flight.

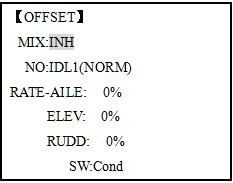

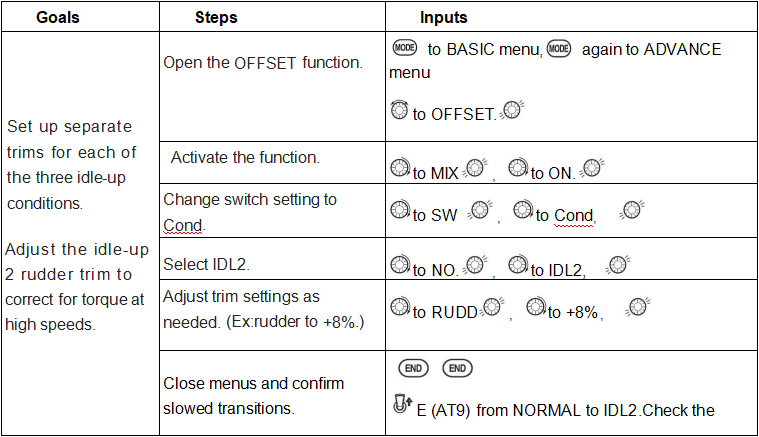

HELI models only: OFFSET is available in the idle ups. If OFFSET is inhibited, adjustment of the TRIM LEVERS will adjust the trims for all flight conditions. If OFFSET is active, then moving the trims within any one condition will affect only that condition.

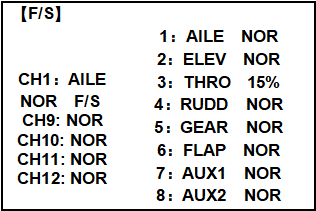

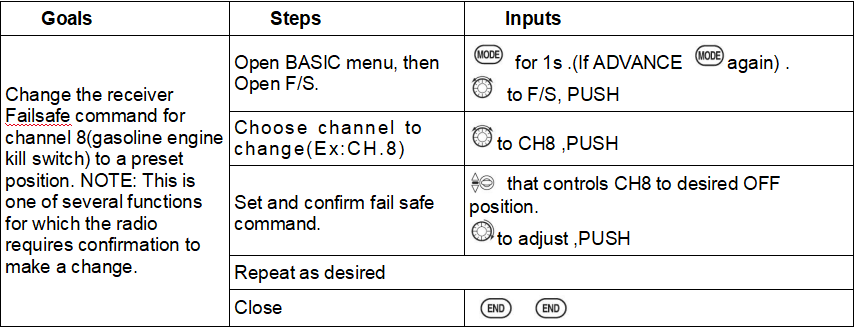

2.11 Fail Safe (F/S)

(loss of clean signal and low receiver battery) submenu (F/S): sets responses in case of loss of signal or low Rx Battery.

Adjustability:

•Each channel may be set independently.

• The NOR (normal) setting holds the servo in its last commanded position.

• The F/S (Failsafe) function moves each servo to a predetermined position.

• NOTE: the setting of the throttle's F/S also applies to the Battery F/S.

• The F/S is used in certain competitions to spin the MULTIROTOR to the ground prior to flying away and doing potential damage elsewhere. Conversely, may also be used to go to neutral on all servos, hopefully keeping the plane flying as long as possible.

• Competition modelers often maintain the NOR function so that brief interference will not affect their model's maneuver.

• Set the throttle channel so that the engine idles when there is interference (ACRO). This may give enough time to fly away from and recover from the radio interference and minimize damage if crashed.

• For helicopters, NOR is typically the safest choice.

•We also recommend setting a gasoline engine's electronic kill switch to the OFF position in the F/S function for safety reasons.

If you specify a F/S setting, the Failsafe data is automatically transmitted once each two minutes. (PCM) When you choose the F/S mode, check that your settings are as desired by turning off the transmitter power switch and verifying that the servos move to the settings that you chose. Be sure to wait at least two minutes after changing the setting and turning on the receiver power before turning off the transmitter to confirm your changes have been transmitted.

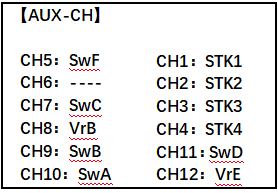

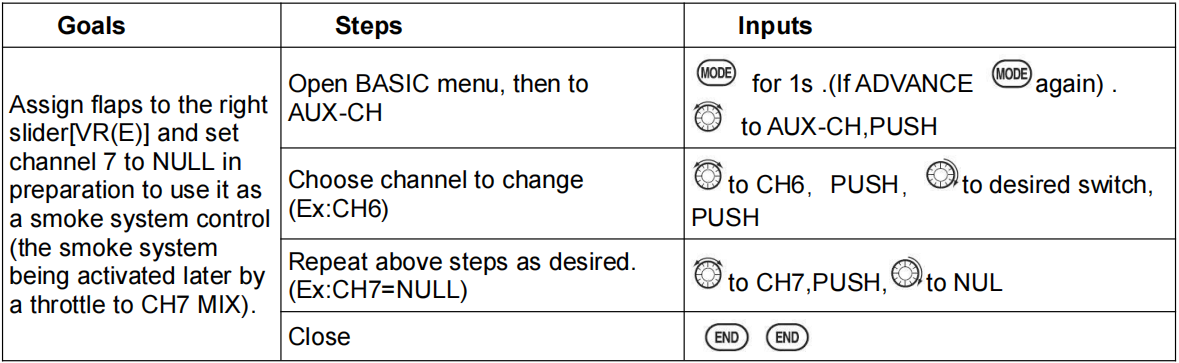

2.12 Auxiliary Channel (AUX-CH)

Auxiliary channel: The auxiliary channel switch is used to do some auxiliary functions, such as opening or closing the throwing chamber, opening or closing the control machine that releases smoke, etc. Each auxiliary channel can be customized with any switch, slider or knob to control (The slider knob is usually used in the pan/tilt camera), or multiple channels can be set on the same switch, slider or knob, and the setting effect can be viewed on the'rudder amount display' interface of the remote control.

Vehicle and ship models generally have 2 basic channels, and airplane models generally have 4 basic channels. All channels except for the basic channels of the remote control are auxiliary channels.

AT9S Pro can not only customize the auxiliary channels, but also customize the 4 basic channels to meet the personalized needs of model friends to a greater extent. The specific setting methods are as follows:

Long press the Mode button for 1 second to enter the basic menu, turn the PUSH button to select 'System Settings', tap the Push button for 1 second to enter the 'System Settings' menu, then select the' Joystick Mode' to "—", tap End once Key to return to the basic menu interface, and then use the PUSH key to select "auxiliary channel" to see the following interface.

Related channels:

GYRO SENSE (ACRO): CH. 5, 7, or 8

GYRO SENSE (HELI): CH. 5

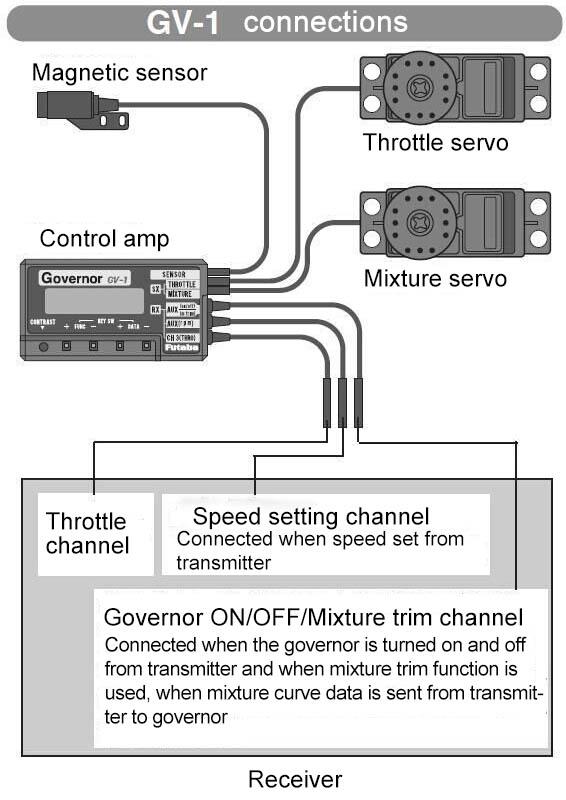

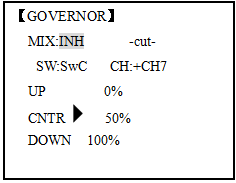

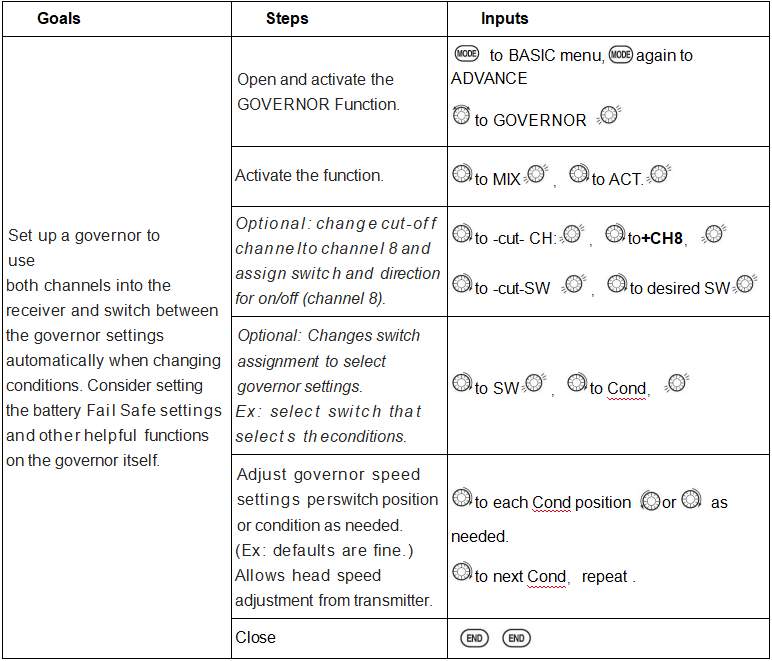

GOVERNOR (HELI): CH. 7, or CH. 7 and 8

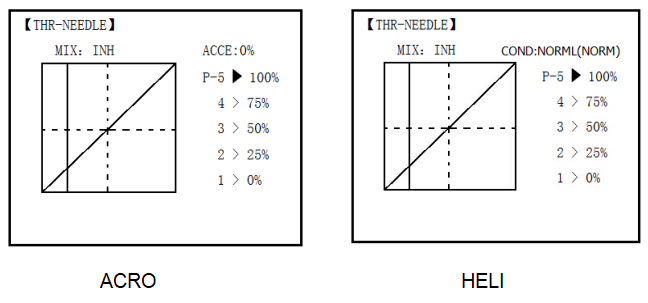

THR-NEEDLE (ACROHELI): CH. 8

Remember that if you assign primary control of a channel to a switch which you later use for other functions (like dual/triple rates or air brakes), every time you use that other function you will also be moving the auxiliary channel.

Remember that if you assign primary control of a channel to a switch which you later use for other functions (like dual/triple rates or air brakes), every time you use that other function you will also be moving the auxiliary channel.

GOVERNOR (HELI): ch. 7, or ch. 7 and 8

Note: 1. When you move one switch, but there are movements in 2 channels, please check if you have set the same switch for two channels.

2. If the function such as gyro sense, throttle-needle is turned on, the switch for the auxiliary channel is invalid.

3. The default channel of AT9S Pro is 10CH. If you use it with 12 channel receiver, pleased change the channel to 12CH.

4. SwA—SwH: 2 position or 3 position switch in the transmitter.

VrA—VrD: two knobs and slide bars

STK1—STK4: the four sticks in the transmitter. STK1 means the right stick, left and right. STK2: the left stick, up and down. STK3: right stick, up and down. STK4: left stick, left and right.

Null means the channel is invalid.

Ls1—Ls3: logic switch

RSSI: The channel can transfer RSSI to flight controller individually. You can set channel 5 to channel 12 to transmit RSSI.

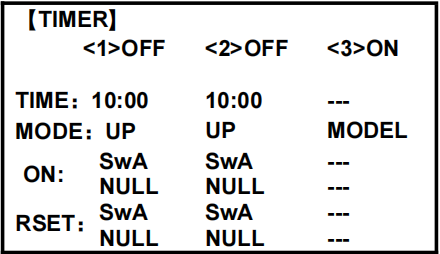

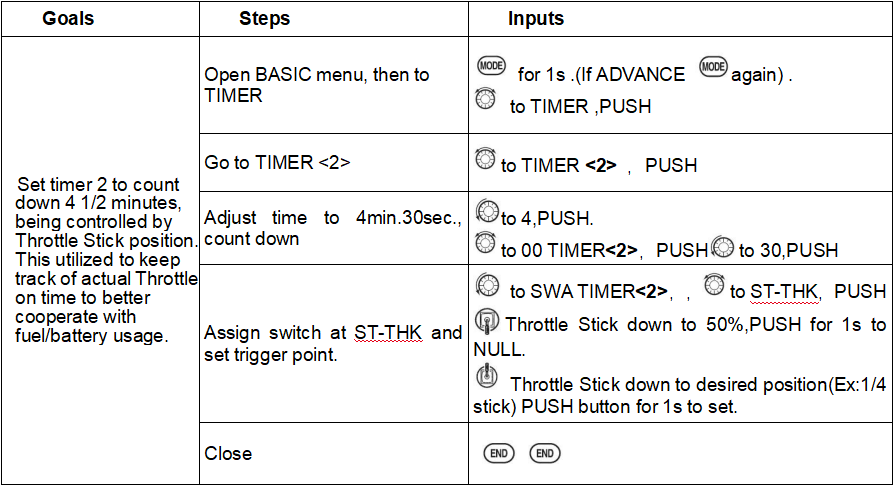

2.13 TIMER

Controls three electronic clocks used to keep track of time remaining in a competition time allowed, flying time on a tank of fuel, amount of time on a battery, etc.

Adjustability:

• Count down timer: starts from the chosen time, displays time remaining. If the time is exceeded, it continues to count below 0.

• Count up timer: starts at 0 and displays the elapsed time up to 99 minutes 59 seconds.

• Count down timer (Stop type): starts from the chosen time, displays time remaining, and stops at 0.

• Model timer: cumulates ON time up to 99 hours 59 minutes each model. Once Model timer function is turned off, the cumulate time will also be reset to "0:00".

• Independent to each model, and automatically updates with model change.

• In either TIMER mode, during the last twenty seconds, there's a beep each second. During the last ten seconds, there's two beeps each second. A long tone is emitted when the time selected is reached. (UP/DOWN TIMER)

• To Reset, choose the desired timer with the CURSOR lever (while at the startup screen), then press and hold DIAL for 1 second.

• Activation by either direction of SWITCH A-H, by THROTTLE STICK (STK-THR) (Using the THROTTLE STICK is convenient if you are keeping track of fuel remaining, or for an electric, how much battery is left), by LOGIC SWITCH Lsw1-Lsw3 or by the power SWITCH (PWR SW).

• Also the reset switch can be assigned (SWITCH A-H or LOGIC SWITCH Lsw1-Lsw3)

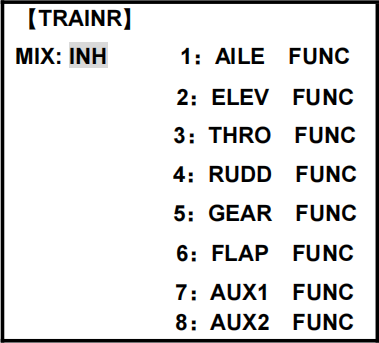

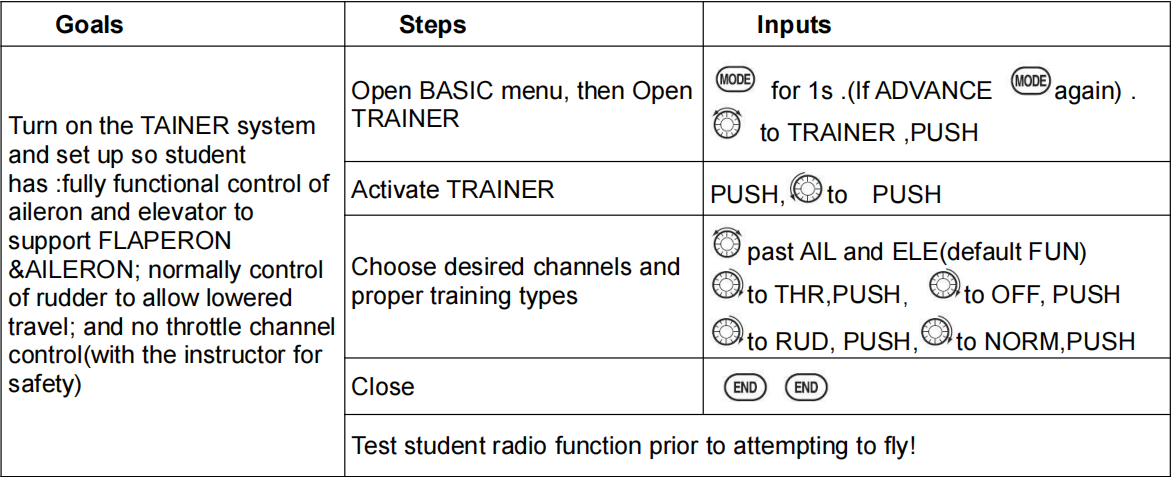

2.14 TRAINER

For training novice pilots with optional trainer cord connecting 2 transmitters. The instructor has several levels of control.

Mode: Hold/Trigger

Hold: Keep pushing the trainer switch (SWH) to make the drone controlled by instructor transmitter. If you loosen the SWH, it will switch to be controlled by student transmitter.

Trigger: Push the trainer switch(SWH) once to make the drone controlled by instructor transmitter. Push the trainer switch(SWH) once again to make the drone controlled by student transmitter.

Adjustability:

• NORM: When the TRAINER SWITCH is ON, the channel set to this mode can be controlled by the student. The set channel is controlled according to any programming set at the student's transmitter.

• FUNC: When the TRAINER SWITCH is ON, the channel set to this mode can be controlled by the student, controlled according to any mixing set at the instructor's transmitter.

• MIX: When the TRAINER SWITCH is ON, the channel set to this mode can be controlled by both the student and the instructor, controlled according to any mixing set at the instructor's transmitter. And the student's mixing rate is adjustable. (Default 30%)

[Note] However, it becomes invalid even if it sets up the channel which is not in a student's transmitter. The channel serves as operation by the instructor's transmitter automatically.

• OFF: The channel set to this mode cannot be controlled by the student even when the TRAINER SWITCH is ON. The set channel is controlled by the instructor only, even when the TRAINER SWITCH is ON.

• SWITCH: controlled by spring-loaded SWITCH H only. Not assignable.

• Compatibility: The AT9S Pro may be master or student with any Radiolink transmitter compatible with the cord. Simply plug the optional trainer cord (For AT9S Pro series, sold separately) into the trainer connection on each transmitter, and follow the guidelines below.

EXAMPLES:

•When throttle/collective is set to FUNG, 5-channel helicopter practice is possible with a 4-channel transmitter.

• Set up the model in a second transmitter, use NORM mode to quickly and safely check proper operation of all functions, and then allow the student radio to fully fly the model.

• Using NORM mode, set lower throws, different exponentials, even different auxiliary channel settings on the student radio (if it has these features).

• To ease the learning curve, elevator and aileron may be set to the NORM or FUNC mode, with the other channels set to OFF and controlled by the instructor.

NOTE:

NOTE:

• NEVER turn on the student transmitter power.

•ALWAYS set the student transmitter modulation mode to PPM.

• BE SURE that the student and instructor transmitters have identical trim settings and control motions. Verify by switching back and forth while moving the control sticks.

• FULLY extend the instructor's antenna. Collapse the student's antenna. (Except 2.4GHz)

• When the TRAINER function is active, the snap roll function is deactivated. Other functions, such as IDLE-DOWN and THR-CUT, which have been assigned to the same switch, are not deactivated. Always double check your function assignments prior to utilizing the TRAINER function.

•When you select a different model, the TRAINER function is deactivated in the current model for safety reasons.

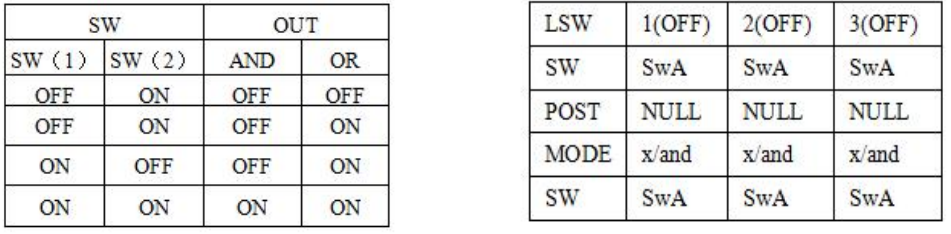

2.15 Logic Switch Selection (LOGIC SW)

The various functions in the AT9S Pro can be selected by switch..

The Logic switch can be assigned to the functions as following: THR-CUT, IDLE DOWN, AUX-CH, TIMER, PROG. MIX, AIRBRAKE, ELEV-FLAP, and AILE-FLAP. The logic switch can activate functions by two switches combination. The 2 types of logic, either AND or OR, can be selected.

Adjustability:

• Three logic switches can be used. (LSW1, LSW2, and LSW3 )

• SW (1): Any SWICH A-H or THRSTKS, SW (2): Any SWICH A-H

• Switch position (POSI)

• Logic mode: AND or OR (MODE)

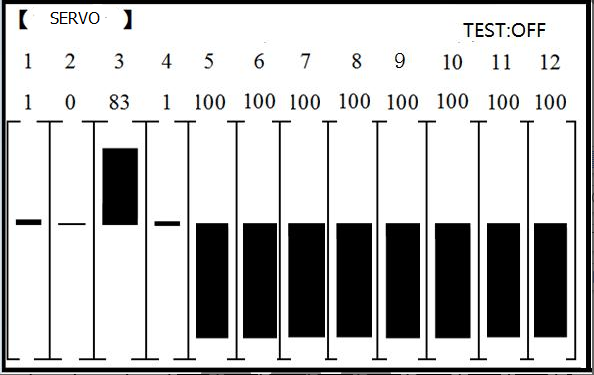

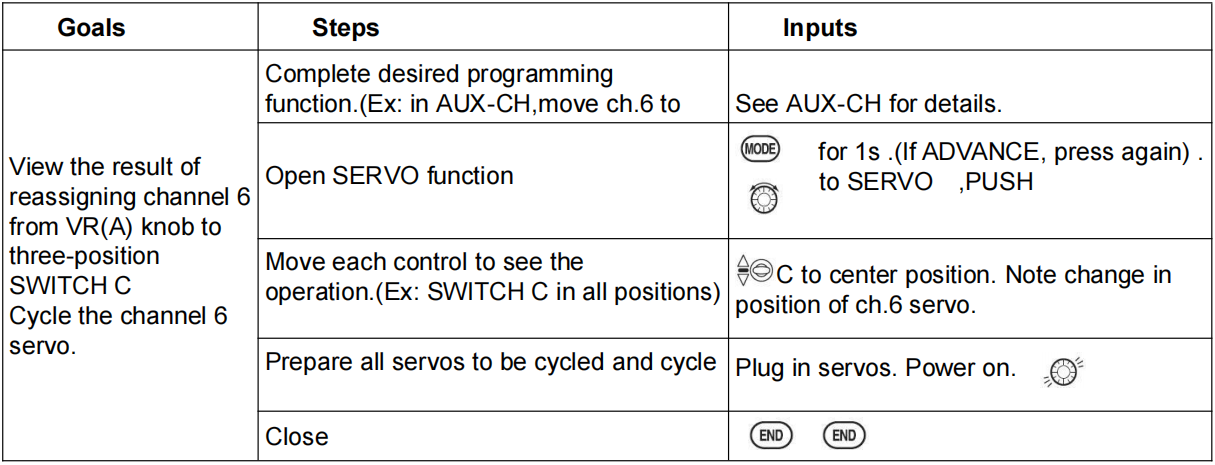

2.16 SERVO

Displays radio's output to channels 1-12(defualt 10 channels, you can upgrade firmware to 12 channels)

The servo submenu includes two features:

• Real-time bar-graph display to demonstrate exactly what commands the transmitter is sending to the servos. (This can be particularly handy in setting up models with complicated mixing functions, because the results of each stick, lever, knob, switch input and delay circuit may be immediately seen.)

• Servo cycle function to help locate servo problems prior to in-flight failures. (Channels 1-8)

2.17 TELEMETRY

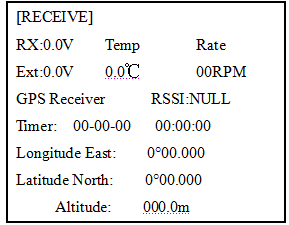

Signal strength and receiver voltage integrated into the radio transmitter. It is displayed as the following configure, also it is in the sub menu RECEIVE.

Receiver voltage is shown as RX,

External voltage is shown as EXT.

Find telemetry information: under BASIC MENU, select RECEIVE, presses PUSH to enter, you can find the telemetry info, shown as below. RX is receiver voltage, EXT is external voltage. Also temperature and engine speed (EXT, TEMPERATURE, RPM, and GPS all need telemetry sensor).

RSSI is signal strength, NULL is for no signal, and 0 is for max.

Connection of telemetry sensor: sensor of EXT, TEMPERATURE, RPM, GPS can connect one by one with the receiver port DATA.

Connection between R9DS and telemetry module PRM-01(pic below on left)

Connection between R9DS and OSD telemetry module PRM-03 with PIXHAWK (pic below on right).

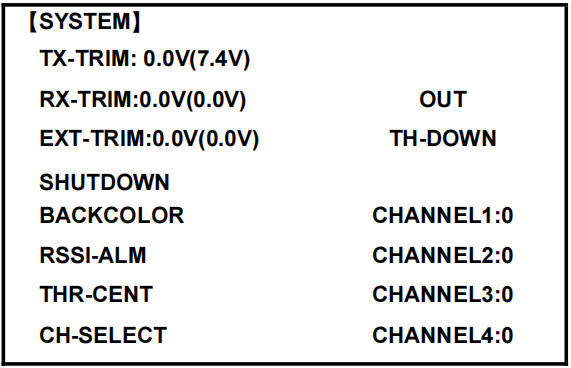

2.18 SYSTEM SETTING

TX-TRIM/ RX-TRIM/ EXT-TRIM: When the telemetry voltage is different from the real voltage, adjust them to the same. The range of adjustment is from -1.0V to +1.0V.

SHUTDOWN: Set a clock to remind turning off the transmitter. When it is at setting time, the transmitter will vibrate and beep. Press Push to turn off the alarm.

BACKCOLOR: There are black and white.

RSSI-ALM: RSSI is the telemetry signal. It’s best to get close to 0. Users can set RSSI alarm when remote flight. Set it off to turn off the alarm.

THR-CENT: Normally, the throttle stick won’t go back to central position. Users can set it on if it’s hard to find the central position for throttle. If the sound of the transmitter is on, there is vibration and sound when the throttle stick is in central position. If the sound of the transmitter is off, there is only vibration when the throttle stick is in central position. So the sound is recommended when THR-CENT is on.

CH-SELECT: It defaults to 10CH. When using 12CH receiver such as R12DS/R12DSM, set it to CH12. When using receivers which are not 12CH, set it to 10CH.

OUT: The signal output of the simulator port at the back of ATPS Pro includes CRSF/SBUS/PPM. It defaults to PPM. Set it to PPM when connecting simulator. Set CRSF when connecting TBS Crossfire transmitter. Set SBUS when connecting FPV and other devices.

TH-DOWN: When the throttle is not at the lowest position, there is TH-DOWN alarm when turning on the transmitter. Set it off to turn off the function.

PART 3. AT9S Pro ADVANCE MENU FUNCTIONS

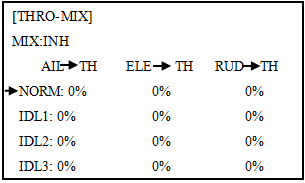

This section will explain the functions in the advanced menu of the transmitters for different models. Before that, I will give you a brief overview of the concept of mixing. In our common models, if the autopilot (flight control) or other flight-assisting functional modules are not used, we will use the remote control to control the model by connecting the steering gear directly to the receiver. That is pure manual control. The steering gear on the model responds to the control of the remote controller. When we use one channel to control the same type of steering surface on the aircraft, we don’t need to turn on any mixing settings. For example, a single steering gear is connected to channel 1 to control the dual ailerons. When the wings and two servos are connected in parallel (Y line) to control the two ailerons of the aircraft on channel 1, there is no need for mixing settings. When the two servos are plugged into two different channels of the receiver respectively to control the two ailerons of the aircraft at the same time, and the two servos are inserted in different channels to control the two lifts of the aircraft at the same time, it is necessary to control the two channels connected to the receiver without affecting the normal operation of the basic channel. Set it up so that the same joystick can control two or more channels at the same time, to achieve mixing control.

The mixing control looks complicated, but it is the best tool to simplify the operation when used properly. When the Y wire is used for connection, the probability of poor contact or insufficient power supply in the servo wiring will greatly increase, which will reduce the safety factor of the aircraft. Using mixing to connect each servo separately to the receiver channel can solve this problem well. When the elevator uses dual steering gears, usually one forward steering gear and one reverse steering gear are used in parallel, but when the steering gear is removed and stored, it is very troublesome to distinguish which one is forward and backward when needed. At present, most of the forward steering gears on the market are forward steering gears. If mixing is used, two forward steering gears can be used to separately connect the receiver channels to control the elevators, which can save a lot of trouble.

Most of the content in this part is to introduce the mixing control function. You can choose to set up a mixing control that is more suitable for your model according to your needs.

3.1 ACRO ADVANCE FUNCTION MENU

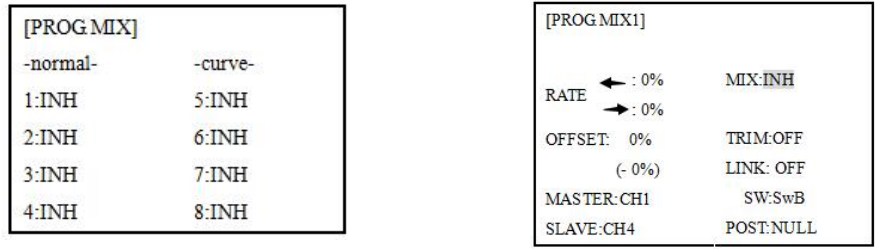

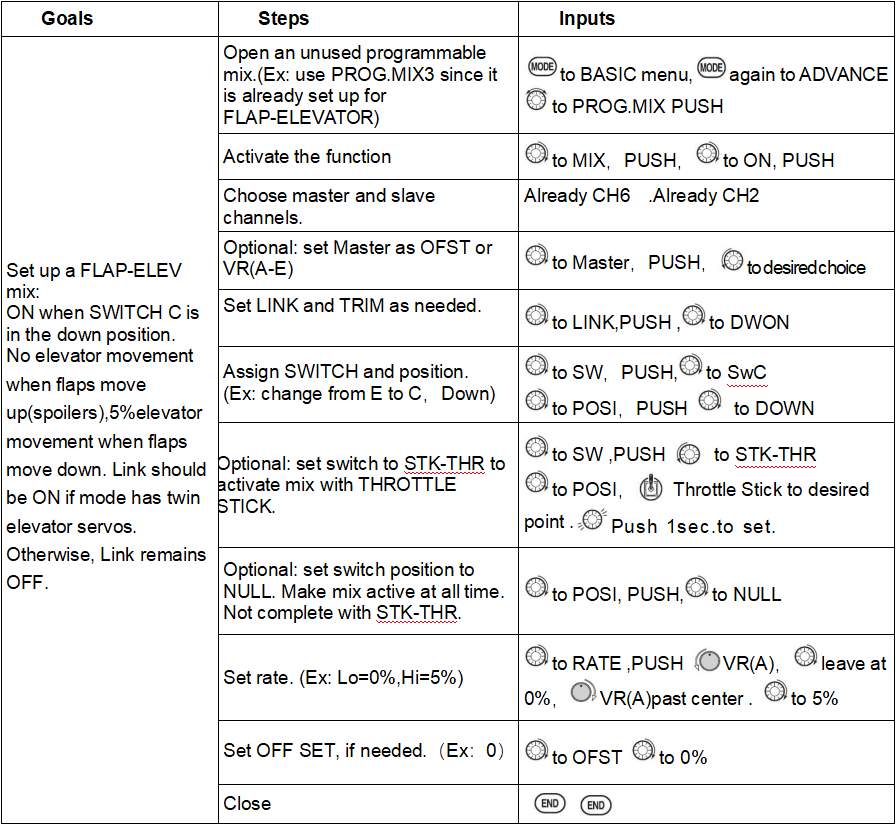

3.1.1 Programmable MIX

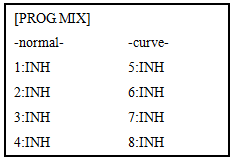

AT9S Pro contains four separate linear programmable mixes. (Note that mixer #5-8’s mixing RATE are set with a 5-point curve. HELI has mixer #5-6's mixing. See CURVE MIXES

There are a variety of reasons you might want to use these mixes. A few are listed here. All of the adjustable parameters are listed below, but don’t let them scare you. For your first few times experimenting with mixes, just turn on the default mixes, adjust them how you think they need to be, then use the servo screen to check and see if you were correct. As with all functions, a sample

setup follows, step by step, to assist you.

Sample reasons to use linear programmable mixes:

• To correct bad tendencies of the MULTIROTOR (such as rolling in response to rudder input).

• To operate 2 or more servos for a single axis (such as two rudder servos).

• To automatically correct for a particular action (such as lowering elevator when flaps are lowered).

• To operate a second channel in response to movement in a first channel (such as increasing the amount of smoke oil in response to more throttle application, but only when the smoke switch is active).

• To turn off response of a primary control in certain circumstances (such as simulating one engine flaming -out on a twin, or throttle-assisted rudder turns, also with a twin).

Adjustability:

• Defaults: The 4 programmable mixes default to the most frequently used mixes for simplicity. If you want to use one of these mixes, simply select that mix number so that the master and slave servos are already selected for you.

• PROG.MIX1 aileron-to-rudder for coordinated turns

• PROG.MIX2 elevator-to-flap for tighter loops (HELI mixes default to ELEV-to-pitch.)

• PROG.MIX3 flap-to-elevator to compensate pitching with flaps (HELI mixes default to pitch-to-ELEV)

• PROG.MIX4 throttle-to-rudder ground handling compensation

•Channels available to mix: All four mixes may use any combination of CH1-8. (CH9-10 is not proportional and cannot be mixed.) Offset and dials may also be set to the master channels.

•Master: the controlling channel, the channel whose movement is followed by the slave channel.

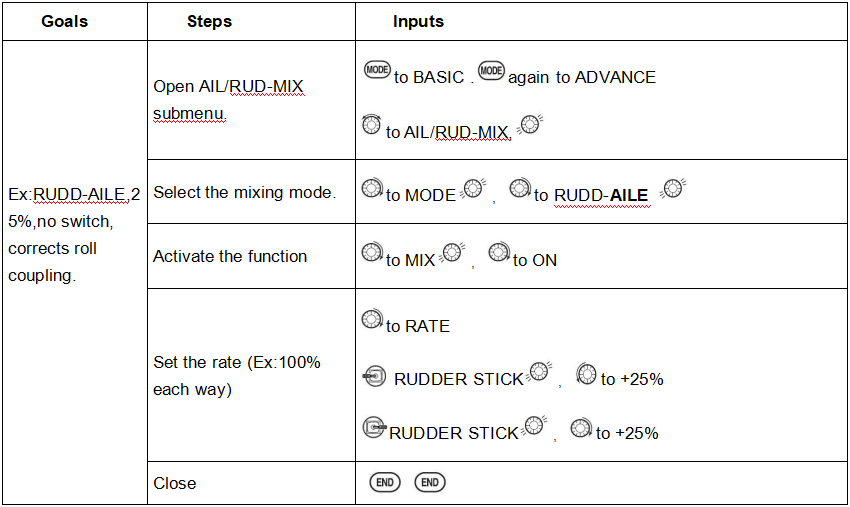

•Another channel: Most mixes follow a control channel. (Ex: rudder-to-ailerons, 25%, no switch, corrects roll coupling.)

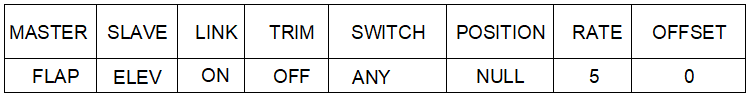

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

RUDD | AILE | ON | OFF | ANY | NULL | 25% | 0 |

•Offset as master: To create an OFFSET mix, set the master as OFST. (Ex: Move FLAPERON as flaps 20% of their total throw when SWITCH C is in down position.)

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

OFST | FLAP | ON | N/A | C | DOWN | 20% | 0 |

• Dial as master: To directly effect one servo’s position by moving a dial, set the master as the desired dial. (Ex: create a second throttle trim on left slider.)

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

VR(D) | THRO | OFF | N/A | ANY | NULL | 5% | 0 |

•Slave: the controlled channel. The channel is moved automatically in response to the movement of the master channel. The second channel is in a mix’s name (i.e. aileron-to-rudder).

•Link: Link this programmable mix with other mixes.

Ex: PMIX FLAP-ELEVATOR mixing to correct for ballooning when flaps are lowered, but model has a V-tail. Without LINK, this mix only moves CH2 elevator when flap is commanded, resulting in a dan

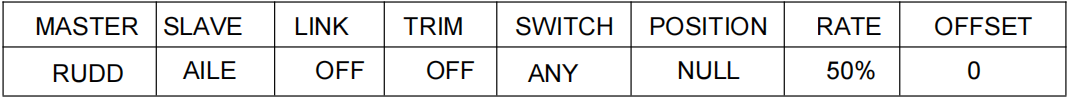

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

RUDD | AILE | OFF | OFF | ANY | NULL | 50% | 0 |

gerous combination of yaw and roll. With LINK ON, mixing is applied to both CH2 and CH4.

•Trim: Master’s trim affects slave. Not displayed if master is not CH 1-4, because 5-9 have no trim. Ex: two rudder servos. With TRIM OFF, rudder trim would bind the two servos. TRIM ON resolves this.

• On/off choices:

• SWITCH: Any of the positions of any of the 8 switches may be used to activate a mix. Up&Cntr, Cntr&Dn options allow the mix to be ON in 2 of the 3 positions of a 3-position SWITCH.

• NULL: No SWITCH can turn this mix OFF. This mix is active at all times.

• LOGIC SW (Lsw1 to 3) may be assigned.

• STK-THR: Turn on/off by THROTTLE STICK movement. Trigger point/direction are selectable. Ex: OFST-to-(gear doors) mix to open gear doors at idle, which is only active if throttle is below half.

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

OFST | AUX2 | OFF | ON | STK-THR | Stick at 1/2.for 1 sec. | 100% | 0 |

• Rate: the percentage of the slave’s range it will move upon maximum input from the master channel. Ex: RUDDERAILERON mix, 50%. Ail range=1''. When rudder is moved full right, ailerons move 1/2''.

• Offset: Offsets the slave’s center is relative to the master. Ex: Smoke valve opens wider per throttle servo position when smoke SWITCH is ON. Smoke servo’s neutral is moved down from THROTTLE STICK center to the bottom.

MASTER | SLAVE | LINK | TRIM | SWITCH | POSITION | RATE | OFFSET |

THRO | AUX2 | OFF | OFF | E | DOWN | 100% | 100% |

Other samples:

• RUD-ELEV (ACRO GLID) mix: Compensate for pitching up or down when rudder is applied.

• AIL-RUD mix (ACRO): Coordinate turns by applying rudder automatically with aileron input. All model types.

• ELEV-PIT (HELI) mix: Compensate for the loss of lift of tilting the model

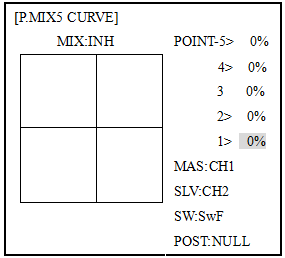

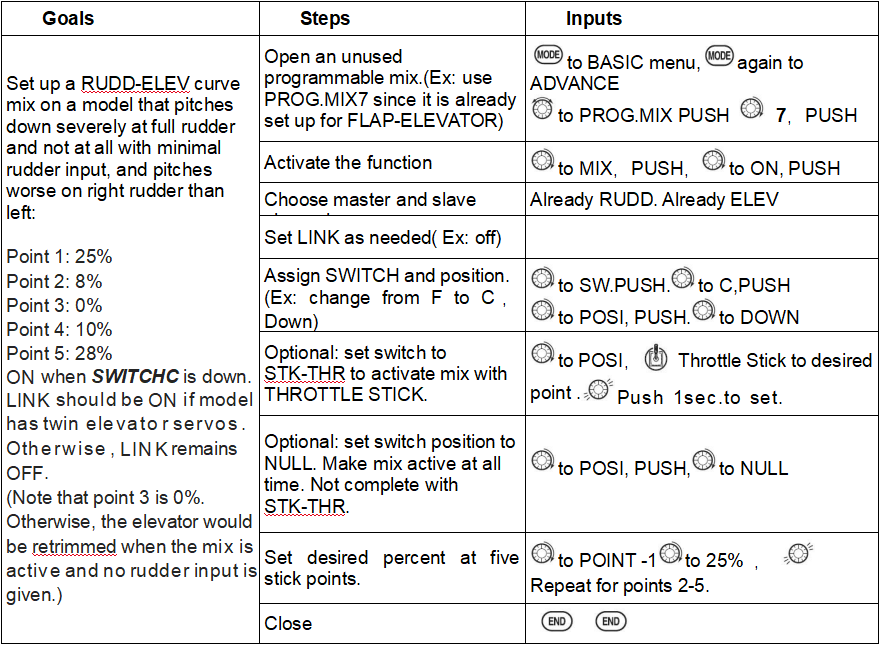

Curve Programmable Mixes (PROG.MIX5-8)(HELI: PROG.MIX5-6 ):

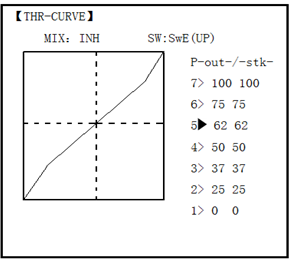

AT9S Pro’s ACRO/GLID programs contain four separate curve programmable mixes. HELI contains two. There are a variety of reasons you might want curve mixes. Usually a linear mix doesn't fit your needs along the whole range. One pre-programmed curve mix is the THROTTLE-NEEDLE function. This curve is adjustable at 5 points, allowing you to adjust the motor’s tuning at 5 points along its RPM range.

One programmable curve mix defaults to RUDDER-AILERON. A linear mix that keeps the model from rolling in knife-edge is probably too much aileron when rudder is applied in level flight. Create a curve mix and set all 5 points to match the linear mix. Inhibit the linear mix, and then adjust the curve to get the right response all along the rudder channel’s travel.

Adjustability:

• ACRO/GLID Defaults: The 4 programmable curves mixes default to the most frequent choices, but can be

set to any channel.

• PROG.MIX5 rudder-to-aileron for roll coupling compensation (GLID mixes default to aileron-to-ELEV.)

• PROG.MIX6 rudder-to-aileron for roll coupling compensation (GLID mixes default to aileron-to-ELEV.)

• PROG.MIX7 rudder-to-elevator for pitch coupling compensation (GLID mixes default to elevator-to-airbrake.)

• PROG.MIX8 rudder-to-elevator for pitch coupling compensation (GLID mixes default to elevator-to-airbrake.)

• HELI Defaults:

• PROG.MIX5 aileron-to-elevator for coordinated turns

• PROG.MIX6 aileron-to-elevator for coordinated turns

• Master: The controlling channel can only be a channel. Cannot OFFSET or dial.

• Trim: not available in curve mixes.

• Offset: not available in curve mixes.

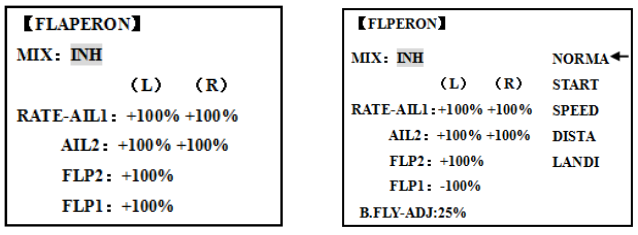

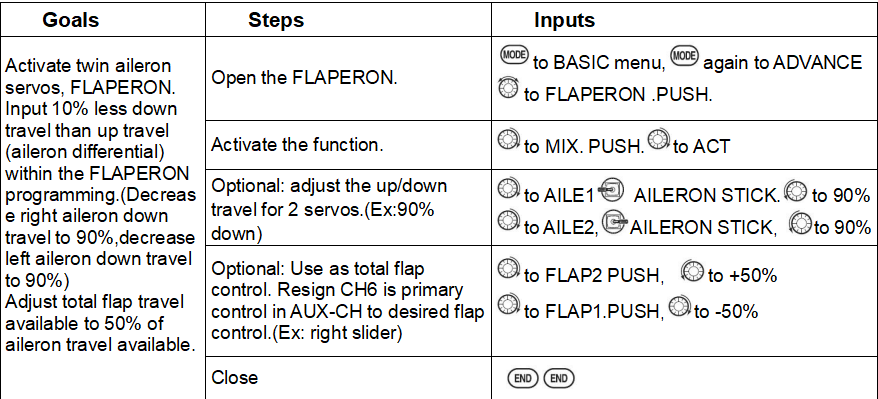

3.1.2 FLAPERON (ACRO/GLID 1A+1F )

The FLAPERON mixing function uses one servo on each of the two ailerons, and uses them for both aileron and flap function. For flap effect, the ailerons raise/lower simultaneously. Of course, aileron function (moving in opposite directions) is also performed.

Note: When changing the polarity of a rate, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

Note: When changing the polarity of a rate, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

Once FLAPERON is activated, any time you program CH6 or "flap" (i.e. ELEVATOR mixing), the radio commands both servos to operate as flaps. The amount of travel available as flaps is independently adjustable in FLAPERON. A trimming feature is also available (see FLAP-TRIM) to adjust both neutral positions together for straight-and-level flight or slight increases/decreases of the flap angle. END POINT and SUB-TRIM both still adjust each servo individually.

Adjustability:

• Each aileron servo up travel can be set separate from its down travel, creating aileron differential. (See example).

• Each aileron servo's travel when actuated as a flap is separately adjustable.

• AILE-2 can be utilized to use a 5-channel receiver and still have FLAPERON. NOTE: The AILE-2 function only commands the channel 5 servo to operate with the aileron servo as ailerons, and to obey the primary flap control (travel adjusted in FLAP-TRIM.) It does not provide full flap mix capability as when using a 6+ channel receiver and channel 6.

• The separate FLAPERON settings for each condition can be set. (GLID)

Note: Activating FLAPERON only makes the ailerons work as ailerons and tells the radio how far you want them to move as flaps. If you then activate other programming that moves them as flaps.

Note: Activating FLAPERON only makes the ailerons work as ailerons and tells the radio how far you want them to move as flaps. If you then activate other programming that moves them as flaps.

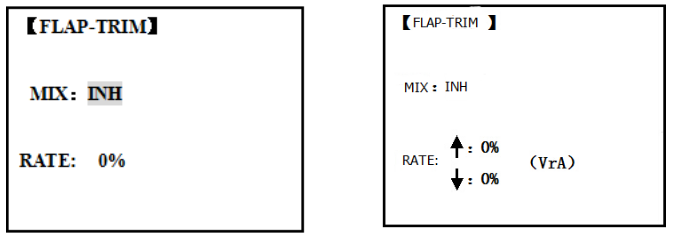

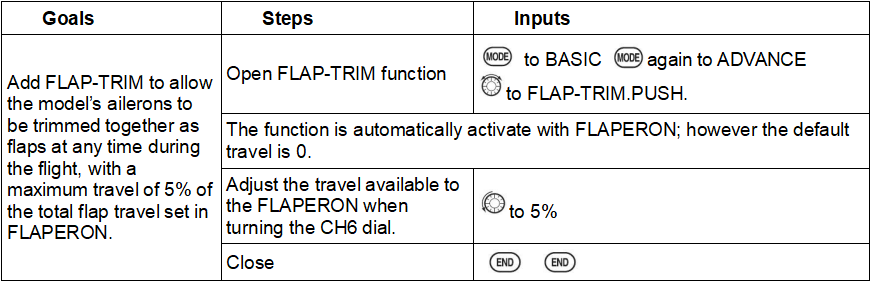

FLAP-TRIM is the flap-trimming feature that allows the flaps to move in reaction to the channel 6 control. It is meant only for trimming the flaps' center but can also be used as full flap control.

ELEVATOR-FLAP would add elevator mixing into the flap movement from the flap dial after FLAP-TRIM is activated.

* If you receive an error message that OTHER WING MIXING IS ON, you must deactivate AIL-DIFF or ELEVON.

3.1.3 FLAP-TRIM

Using FLAP-TRIM to adjust FLAPERON (ACRO/GLID)

FLAP-TRIM assigns the primary FLAPERON control [defaults to VR(A)] to allow trimming in flight of the flap action of FLAPERON.

Note: Even if FLAP-TRIM is made active with AIL-DIFF, it will not have any effect. The ONLY function that allows control of the ailerons as flaps in the AIL-DIFF configuration is AIRBRAKE. Most modelers use AIRBRAKE, or programmable mixes, to move the flaps to a specified position via movement of a switch.

Note: Even if FLAP-TRIM is made active with AIL-DIFF, it will not have any effect. The ONLY function that allows control of the ailerons as flaps in the AIL-DIFF configuration is AIRBRAKE. Most modelers use AIRBRAKE, or programmable mixes, to move the flaps to a specified position via movement of a switch.

FLAP-TRIM may also be used as the primary flap control in flight. By doing so, you can assign CH6 to a 3-position switch, with a "SPOILERON", neutral, and "FLAPERON" position, and even adjust the percentage traveled as FLAPERON/SPOILERON by changing the Flap Trim travel.

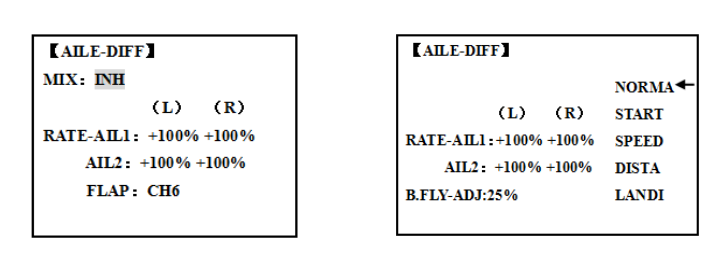

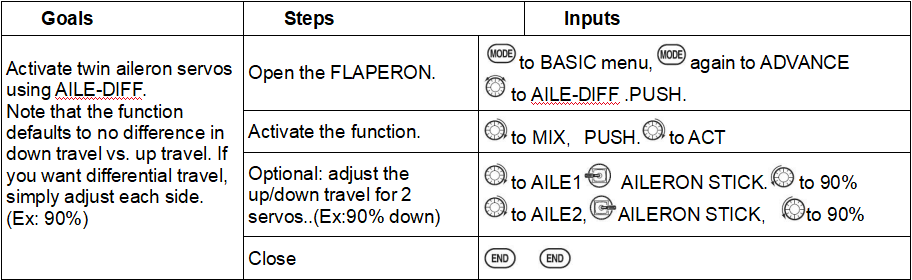

3.1.4 AILE DIFF (ACRO/ GLID 2A+1F/ GLID 2A+2F)

ACRO GLID (2A+1F)/GLID (2A+2F)

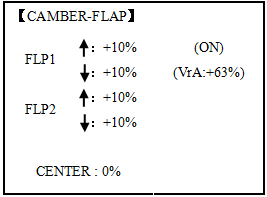

Aileron differential is primarily used on 3 or 4-servo wings, with one servo operating inboard flap on CH6 or CH5 & CH6, and AILE-DIFF controlling proper aileron operation of 2 aileron servos, plugged into CH1 and CH7. The ailerons can not be moved like flaps when using AILE-DIFF, except if using AIRBRAKE. (Note that even if you make FLAP-TRIM active while using AILE-DIFF, it will not have any effect. ONLY AIRBRAKE controls the ailerons as flaps in the AILE-DIFF configuration.)

Note: When changing the polarity of a rate in camber-flap, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

Note: When changing the polarity of a rate in camber-flap, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

• FLAP function allows you to set up 1 or 2 servos for flap action.

• The separate AILE-DIFF settings for each condition can be se t. (GLID only)

* If you receive an error message that OTHER WING MIXING IS ON, you must deactivate ELEVON or FLAPERON.

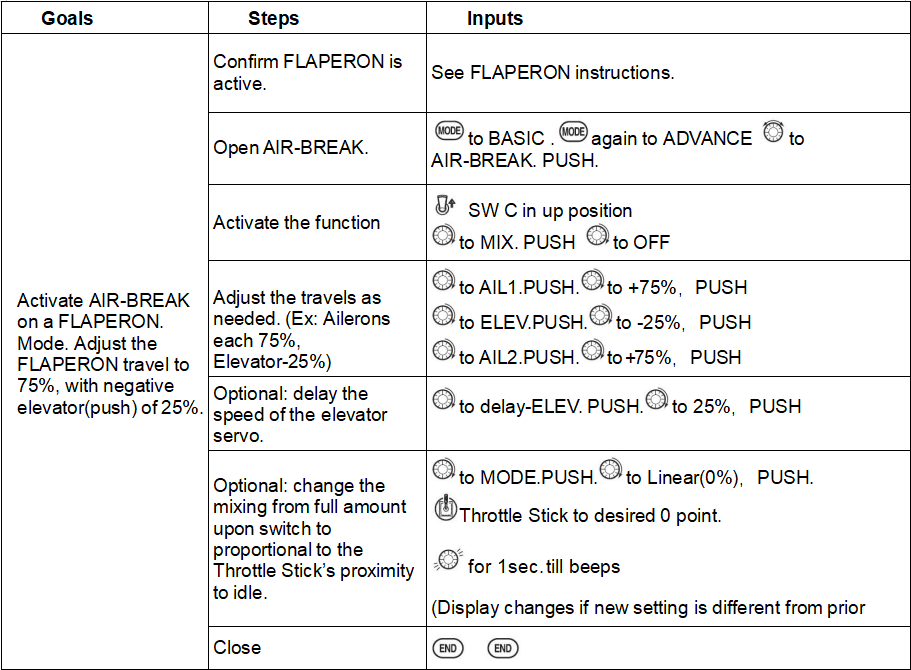

3.1.5 Air Break (ACRO/ GLID)

Like FLAPERON and AILEVATOR, AIRBRAKE is one function that is really made up of a series of pre-programmed mixes all done for you within the radio. AIRBRAKE (often called "crow" or BUTTERFLY - see GLID, p. 62 for details) simultaneously moves the flap (if installed), twin ailerons (if installed) and elevator, and is usually used to make steep descents or to limit increases in airspeed in dives.

This function is often used even on models without flaps as an easy way to use the FLAPERON and FLAP-ELEVATOR mixing together.

Adjustability:

• Activation: be proportional by moving the THROTTLE STICK, or set positions by flipping the assigned switch.

• Switch: Mix SWITCH is selectable.

• Also LOGIC SW (Lsw1 to 3) may be assigned.

• Linear(Inversely proportional to THROTTLE STICK): Provides a proportional increase in amount of AIRBRAKE action as THROTTLE STICK is lowered and assigned switch is on. It provides gradually more AIRBRAKE as you slow the engine. Includes selectable stick position where AIRBRAKE begins, gradually increasing to the same setting as the THROTTLE STICK is lowered. If you would like to have the airbrake be directly proportional to throttle stick, you will

need to reverse the THR-REV function. Note that this changes the throttle stick direction for all models.

• Offset: Provide AIRBRAKE response immediately upon switch movement, going to a pre-set travel on each active channel without any means of in-flight adjustment.

• During Airbrake operation, the elevator travel is displayed on the elevator trim display in the Startup screen.

•Delayed reaction: You can suppress sudden changes in your model's attitude when AIRBRAKEBUTTERFLY is activated by setting the delay (delay-ELEV) item, to slow down the elevator response, allowing the flaps/ailerons/elevator to all reach their desired end point together. A setting of 100% slows the servo to take approximately one second to travel the prescribed distance. (GLID: B.FLY-ELEV function)

• Adjustable in flight (ACRO): Using the aileron (when AILE-DIFF or FLAPERON is activated) and elevator trim lever in flight can be set to adjust the aileron and elevator settings in your airbrake rather than adjusting the model's actual aileron and elevator trim. This allows easy adjustment for any ballooning while in flight. When the airbrake switch is moved to off the trim is again adjusting the normal elevator trim.

• Channels controlled: Elevator, twin ailerons and flap may be set independently in AIRBRAKE, including set to 0 to have no effect.

• If FLAPERON is active, the travel of the ailerons can be independently adjusted for the servos plugged into CH1 and CH6. The flap choice has no effect on the FLAPERON.

• If AIL-DIFF is active, then CH1 and CH7 may be independently adjusted.

• Normally both ailerons are raised equally in AIRBRAKE, and the elevator motion is set to maintain trim when the ailerons rise. Different amounts may be set for each aileron to correct for torque reactions and other unique characteristics of the model.

Be sure you understand what dropping ailerons will do when in AIRBRAKE BUTTERFLY. Along with creating an enormous amount of drag (desirable for spot landings), this also creates "wash-in", a higher angle of attack where the ailerons are, and encourages tip stalling.

Be sure you understand what dropping ailerons will do when in AIRBRAKE BUTTERFLY. Along with creating an enormous amount of drag (desirable for spot landings), this also creates "wash-in", a higher angle of attack where the ailerons are, and encourages tip stalling.

If you are using this for aerobatic performance and not "sudden stops", consider raising the ailerons and dropping the flaps instead as shown in the diagram above.

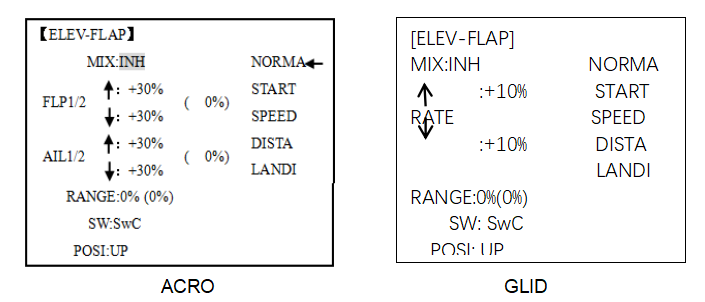

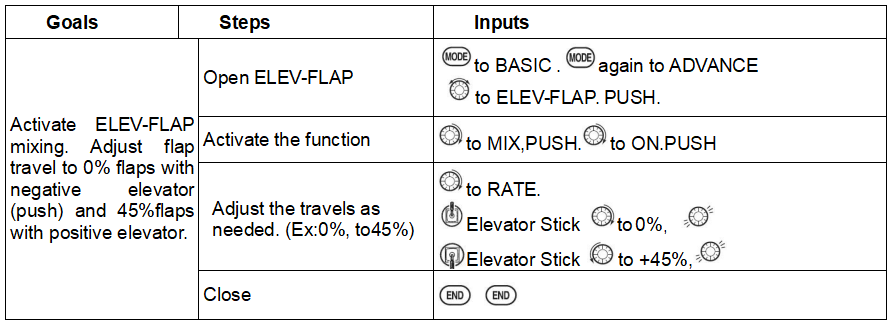

3.1.6 ELEV-FLAP mixing (ACRO/GLID)

ELEV-FLAP mixing is the first pre-programmed mix we'll cover. This mix makes the flaps drop or rise whenever ELEVATOR STICK is moved. It is most commonly used to make tighter pylon turns or squarer corners in maneuvers. In most cases, the flaps droop (are lowered) when up elevator is commanded.

Adjustability:

• Rate: -100% (full up flap) to +100% (full down flap), with a default of +50% (one-half of the flap range is achieved when the ELEVATOR STICK is pulled to provide full up elevator.)

• Switch: Fully assignable. Also LOGIC SW (Lsw1 to 3) may be assigned. IF you set it to NULL, the mix does not work. (ACRO)

•Range (GLID): The range that mixing does not work near neutral of an elevator stick can be set up. Hold the stick to the desired point (upper or lower side) , then press DIAL and hold one second to set the range.

• Condition (GLID): The separate ELEV-FLAP settings for each condition can be set.

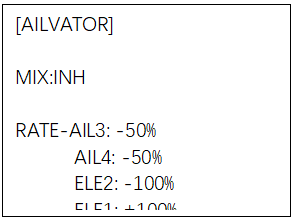

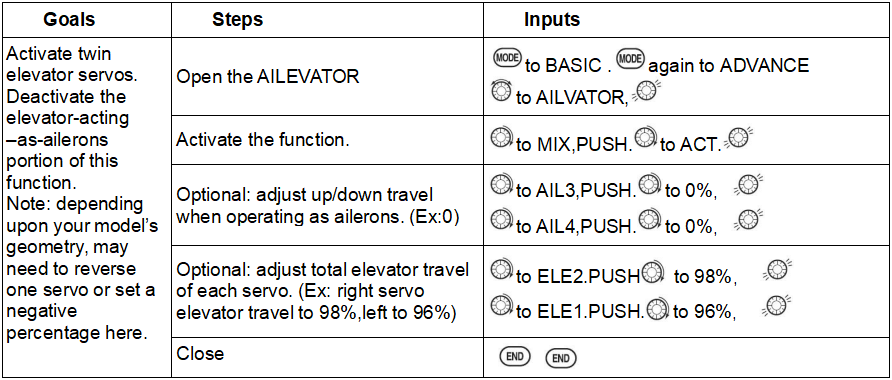

3.1.7 Dual Elevator Servos (with a rudder) (AILEVATOR) (ACRO)

Many models use two elevator servos, plugged in separate receiver

channels. (Flying wings without a separate aileron control use ELEVON.

V-shaped tail models use V-TAIL,

ADVANTAGE:

•Ability to adjust each servo's center and end points for perfectly matched

travel.

• Ease of assembly, not requiring torque rods for a single servo to drive 2

surfaces.

• Elevators acting also as ailerons for extreme stunt flying or more realistic jet flying (optional).

• Redundancy, for example in case of a servo failure or mid-air collision.

Adjustability:

• CH2 and CH8 only. (With programmable mixing, could utilize CH5 as the 2nd elevator servo.

THROTTLE-NEEDLE uses CH8 and cannot be active simultaneously).

• Direction of each servo's travel may be reversed in REVERSE or the set percentages may be reversed here.

• Elevator travels independently adjustable (both directions and percent).

•Optional action as ailerons (defaults to 50% response). This response cannot be activated/ deactivated in flight. Setting AIL1 and 2 to 0 disables this feature.

Note: if you want this, but on/off with a switch, set AIL1 and 2 to 0 here, and use 2 mixes. AIL-to-AUX2 (link/trim off, assign a switch), get aileron action from the elevator servos when the assigned switch is on.

Note: if you want this, but on/off with a switch, set AIL1 and 2 to 0 here, and use 2 mixes. AIL-to-AUX2 (link/trim off, assign a switch), get aileron action from the elevator servos when the assigned switch is on.

The AILEVATOR mixing function uses one servo on each of the two elevators, and combines the elevator function with the aileron function (unless aileron travel is set to 0). For aileron effect, the elevators are raised and lowered opposite of one another in conjunction with the ailerons.’

Once AILEVATOR is activated, unless you zero out the aileron figures (see below), any time you move your ailerons or any programming moves your ailerons (i.e. RUDDER-AILERON mixing), the radio automatically commands both elevator servos to also operate as ailerons. To deactivate this action, simply set the 2 aileron travel settings to 0 in the AILEVATOR function. This way the elevators will work only as elevators.

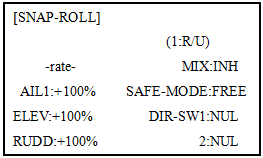

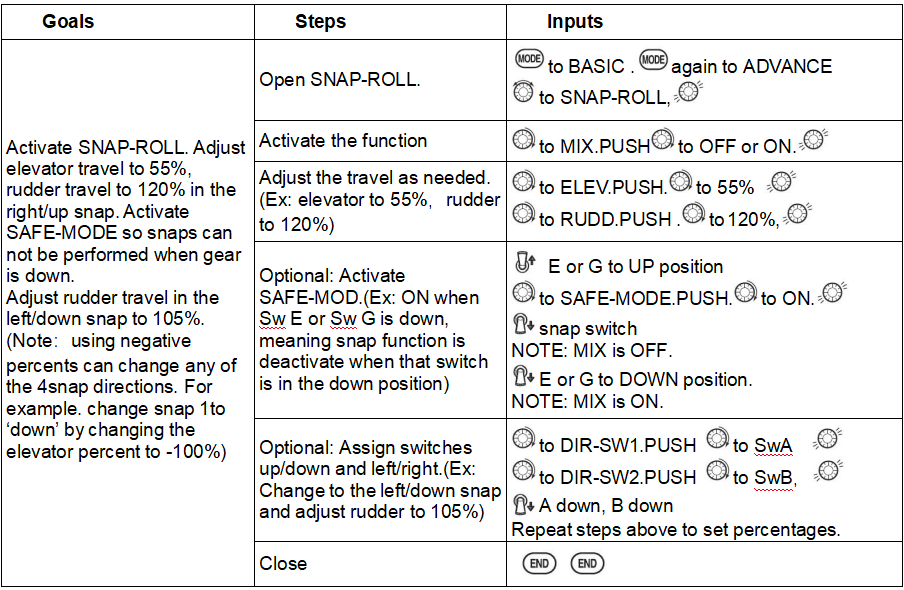

3.1.8 Snap Rolls (ACRO)

This function allows you to execute snap rolls by flipping a switch, providing the same input every time. It also removes the need to change dual rates on the 3 channels prior to performing a snap, as SNAP-ROLL always takes the servos to the same position, regardless of dual rates, inputs held during the snap, etc.

Note: Every MULTIROTOR snaps differently due to its C.G., control throws, moments, etc. Some models snap without aileron; others snap on elevator alone. Most models snap most precisely with a combination of all 3 surfaces. Additionally, rate of speed and acceleration when using the snap switch will affect how the model snaps. For information using gyros with airplanes for cleaner precision maneuvers, such as snaps and spins without over rotation.

Note: Every MULTIROTOR snaps differently due to its C.G., control throws, moments, etc. Some models snap without aileron; others snap on elevator alone. Most models snap most precisely with a combination of all 3 surfaces. Additionally, rate of speed and acceleration when using the snap switch will affect how the model snaps. For information using gyros with airplanes for cleaner precision maneuvers, such as snaps and spins without over rotation.

Adjustability:

• Travel: Adjust the amount of elevator, aileron and rudder travel automatically applied.

• Range: -120 to +120 on all 3 channels. Default is 100% of range of all 3 channels.

• Directions: Up to 4 separate snaps is fully adjustable regarding travels and direction on each of the 3 channels.

Note: for simplicity, the radio refers to snaps that use “UP” or positive elevator as “U” or “UP” snaps. This is more commonly referred to as a positive or inside snap. “D” or “DOWN” snaps are more commonly referred to as negative or outside snaps.

• R/U = Right positive R/D = Right negative L/U = Left positive L/D = Left negative snap roll.

• Assignment of the 2 switches (DIR-SW1/2) to change snap directions is fully adjustable and optional. If you wish to have only one snap, leave the switches as NULL. (If assigned, SW1=up/down, SW2=left/right)

• Safety Switch (SAFE-MOD): a safety may be set up on your landing gear SWITCH, preventing accidental snap rolls while the landing gear is down. The safety switch is turned on and off with the landing gear SWITCH.

• ON: the safety mechanism is activated when the landing gear SWITCH is in the same position as at the time this feature is changed to ON. Snap rolls will not be commanded even if the snap roll SWITCH is turned on with the gear SWITCH in this position. When the landing gear SWITCH is moved to the opposite position, snap rolls may be commanded.

• OFF: Activate the safety mechanism in the opposite position from the ON function.

• FREE: The safety mechanism is completely turned off. Snaps can be commanded regardless of the gear SWITCH POSITION.

Note: The location of the safety switch always follows channel 5. If channel 5 is reassigned to switch C, for example, switch C is now the safety. If channel 5 is null or used as the second aileron servo, the safety function will not be available.

Note: The location of the safety switch always follows channel 5. If channel 5 is reassigned to switch C, for example, switch C is now the safety. If channel 5 is null or used as the second aileron servo, the safety function will not be available.

• Trainer Safety: SNAP-ROLL is automatically disabled when the trainer function is activated.

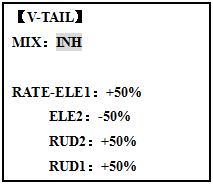

3.1.9 V-Tail (ACRO/ GLID)

V-TAIL mixing is used with v-tail MULTIROTOR so that both elevator and rudder functions are combined for the two tail surfaces. Both elevator and rudder travel can be adjusted independently on each surface.

Note: NOTE: If V-TAIL is active, you cannot activate ELEVON or AILEVATOR functions. If one of these functions is active, an error message will be displayed and you must deactivate the last function prior to activating ELEVON.

Note: NOTE: If V-TAIL is active, you cannot activate ELEVON or AILEVATOR functions. If one of these functions is active, an error message will be displayed and you must deactivate the last function prior to activating ELEVON.

Note: Be sure to move the elevator and rudder sticks regularly while checking the servo motions. If a large value of travel is specified, when the sticks are moved at the same time, the controls may bind or run out of travel. Decrease the travel until no binding occurs.

Note: Be sure to move the elevator and rudder sticks regularly while checking the servo motions. If a large value of travel is specified, when the sticks are moved at the same time, the controls may bind or run out of travel. Decrease the travel until no binding occurs.

Adjustability:

• Requires use of CH2 and CH4.

• Independently adjustable travels allow for differences in servo travels.

• Rudder differential is not available. (To create rudder differential, set RUD1 and 2 to 0, then use two programmable mixes, RUD-ELE and RUD-RUD, setting different percents for up and down. These are your new rudder travels. Trim and link off, switch assignment null so you can’t accidentally turn off rudder.

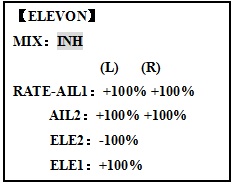

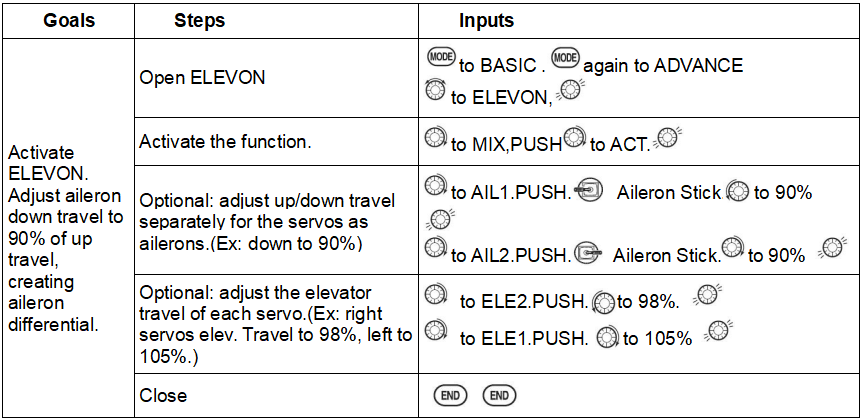

3.1.10 ELEVON

Adjustability:

• Requires use of CH1 and CH2.

• Independently adjustable aileron travel allows aileron differential.

• Independently adjustable elevator travel allows for differences in up vs. down travel.

• The separate ELEVON settings for each condition can be set. (GLID only)

Note: When changing the polarity of a rate, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

Note: When changing the polarity of a rate, "change rate dir?" is displayed for a check. Please set up after pressing DIAL for 1 second and canceling an alarm display. (GLID only)

Note: Be sure to move the elevator and aileron sticks to full deflection during setup. If large travels are specified, when the AILERON and ELEVATOR STICKS are moved at the same time the controls may bind or run out of travel.

Note: Be sure to move the elevator and aileron sticks to full deflection during setup. If large travels are specified, when the AILERON and ELEVATOR STICKS are moved at the same time the controls may bind or run out of travel.

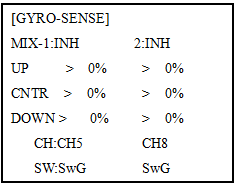

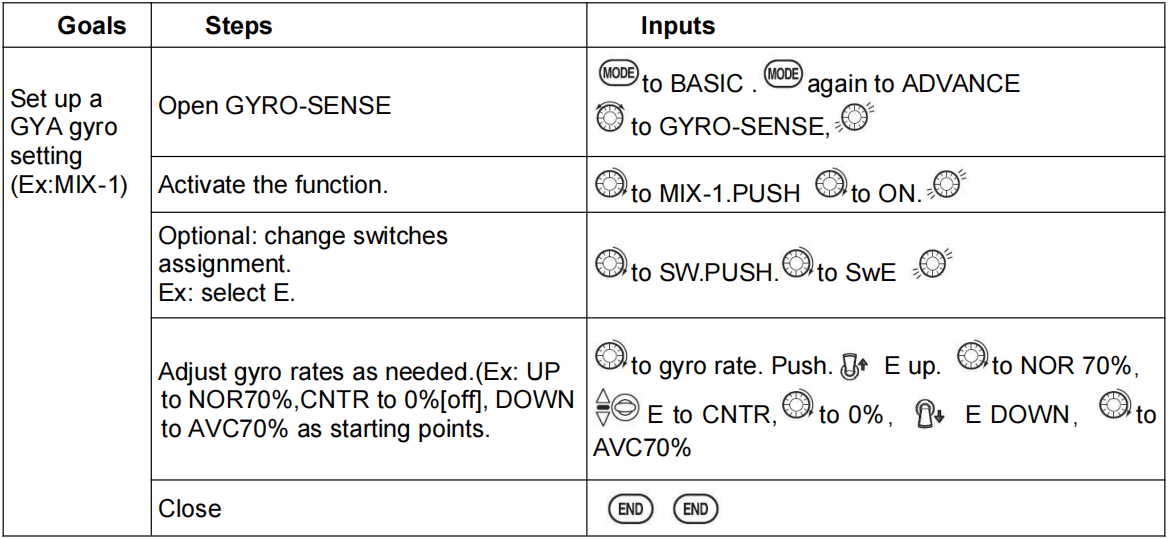

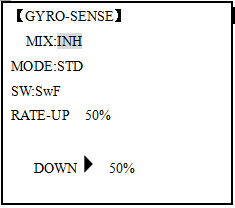

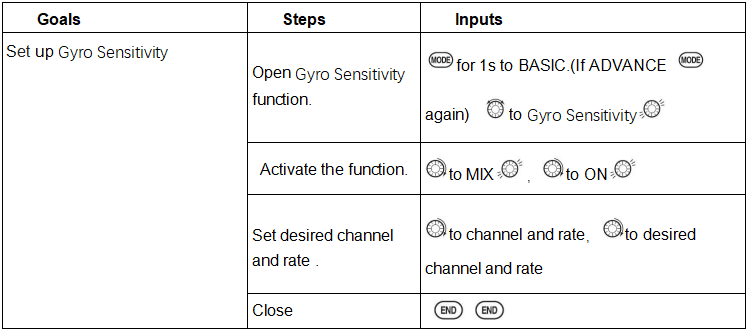

3.1.11 Gyro Sense

The gyros have two operations modes: GY mode and STD mode.

•STD mode: This mode performs general proportional control operation. For instance, it controls the gyro so that changes are countered when the attitude of the MULTIROTOR is changed by cross-wind, etc.

•GY mode: This mode performs both proportional and integrated control operation. The difference between Normal mode and GY mode operation is that where as the Normal mode only counters changes in attitude, the GY mode returns to the original controlled variable simultaneously with countering changes in attitude. For example, during knife edge flying, aileron and elevator meeting rudder is normally necessary, but in the GY mode, meeting rudder is performed automatically by the gyro.

Adjustability:

• Plug the gyro's sensitivity adjustment to channel 5, 7, or 8 of the receiver. (Selectable)

• Full switch assignable (SWITCH A-H)

• Each rate setting may be set from 0 to NOR100% or AVC100% gain. NOR: GY mode gain. AVC: STD mode gain

• Larger percentages indicate more gain, or gyro responsiveness.

• MIX-1,2: Two surfaces' sensitivity can be adjusted independently.

GYRO GAIN Adjustability:

• When the servo hunts, the gyro gain is too high. Lower the gain until the hunting stops.

• The gyro will display best performance at a gain just before hunting occurs. Perform adjusting by flying the MULTIROTOR repeatedly.

Precaution:

Precaution:

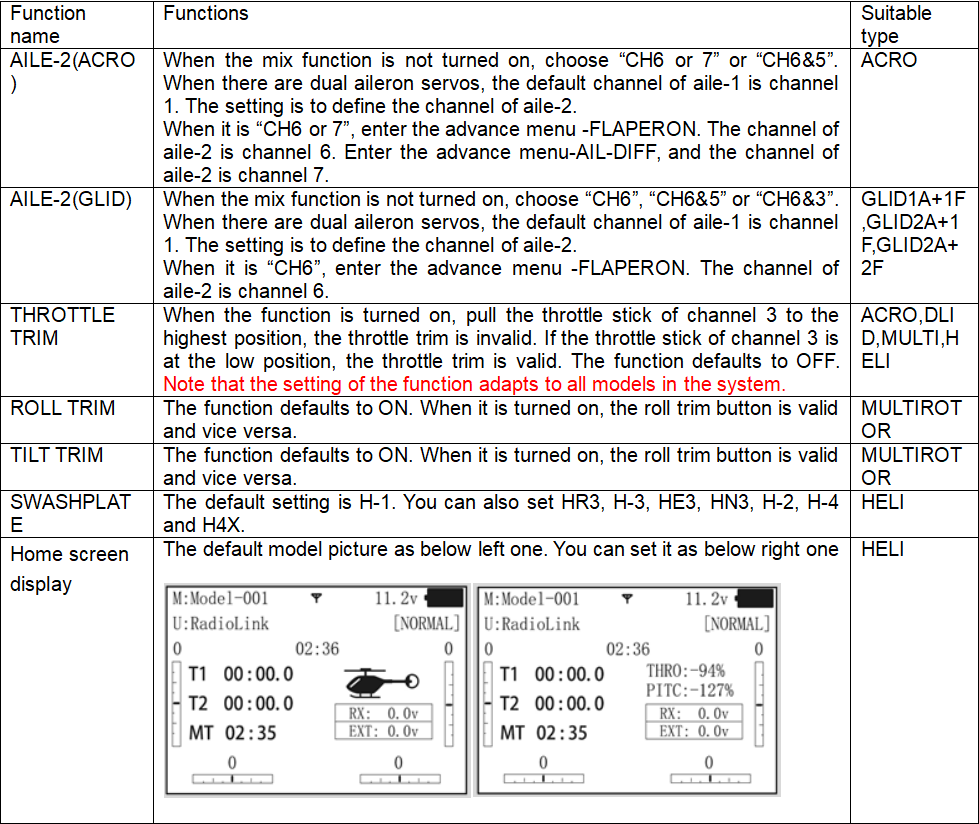

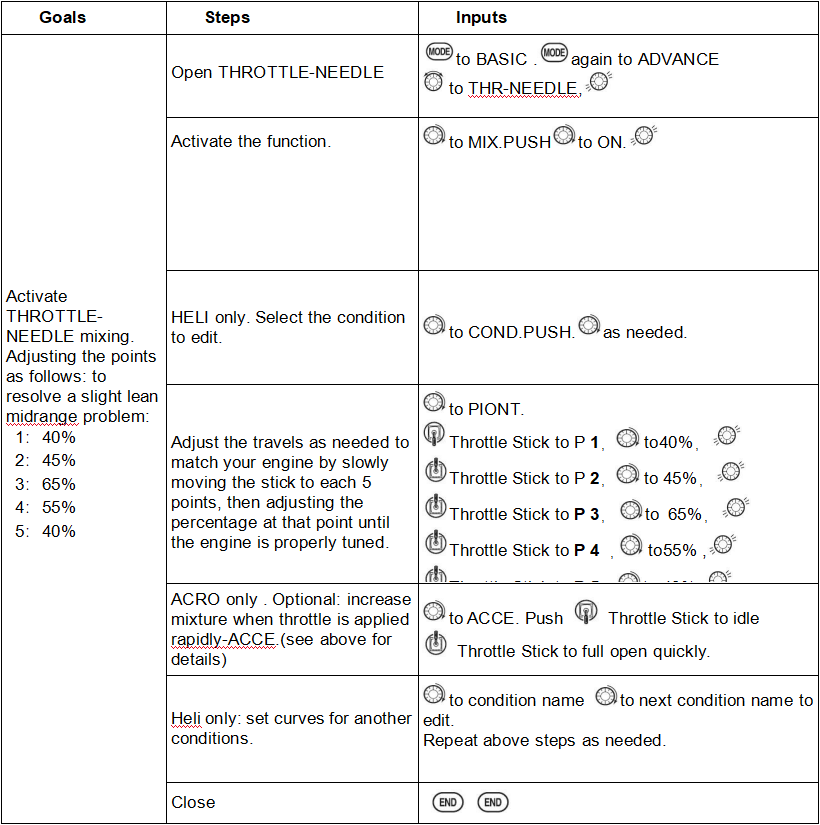

• When taking off and landing, always switch to the Normal mode. Taking off and landing in the GY mode is dangerous.